- Overview

- Recommended Products

| Place of Origin: | CHINA |

| Brand Name: | WEILI |

| Certification: | ISO9001 |

| Minimum Order Quantity: | 1 |

| Price: | Depending on the model number |

| Packaging Details: | Wooden box, waterproof |

| Delivery Time: | 20 days |

| Payment Terms: | 30% deposit,pay the 70% balance before delivery |

| Supply Ability: | Advanced manufacturing capabilities for large-scale orders |

Description

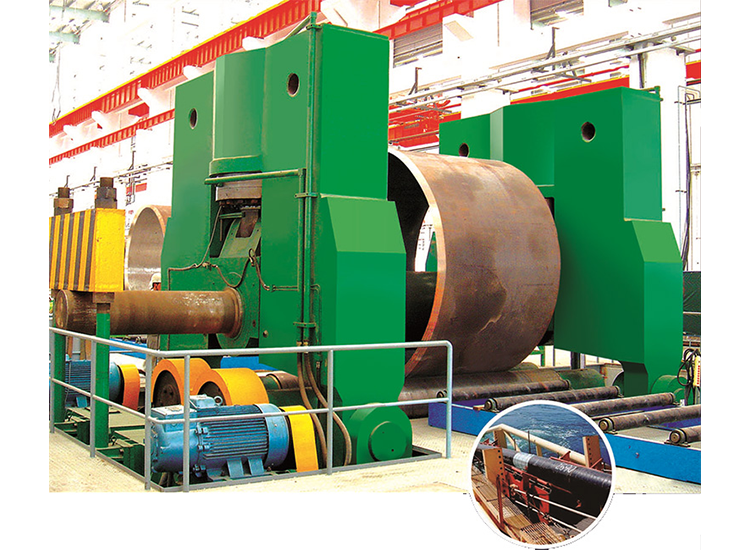

1. The upper roll universal-type coil bender is a type of hydraulic three-roll coil bender that is used to roll sheet metal into cylindrical, curved, or conical shapes under normal temperature conditions.

2. The upper roll can move vertically and horizontally. The vertical movement of the upper roll is controlled by hydraulic transmission, while the horizontal movement is controlled by mechanical transmission.

3. It features a pre-bending function for the edge of the sheet metal. By moving the upper roll horizontally and placing it in an asymmetrical position relative to the lower roll, pre-bending can be achieved.

4. During the rolling process, the two lower rolls are driven by an electric motor and gear reducer. Since the height of the lower roll remains constant, it is convenient for feeding and operation.

5. It is controlled by a PLC programmable display, featuring digital display and easy-to-use operation.

Versatile bending shapes: The upper roll CNC universal-type coil bender can produce various shapes such as O-shaped, U-shaped, and multi-section R-shaped profiles.

Competitive Advantage

1. High-precision end bend, freely set the length of the straight side, and the upper roller directly pressurizes the bend, capable of completing high-precision end bending.

2. NC numerical control, high production efficiency, rolling product process parameters NC, simple operation, efficiency greatly improved.

3. The product accuracy is excellent, the upper roller is a drum shape, the lower side of the lower roller has a pallet adjusted, and the continuous bend is capable of rolling the ideal product from a wide range of thin plates to thick plates.

4. Work safe. The two lower rollers are fixed, the upper roller is moved up, down, and around, the workpiece does not move with the working roller, and the worker is safe.

5. Integral construction, simple foundation, easy to move, the equipment adopts integral chassis, without holding down bolt, simple foundation, convenient to move working place.

6. Different uses, the corresponding numerical control method, according to the use, there are the following numerical control methods: TNC (NC): multiple varieties, small quantities of production; T & BNC (Upper and Lower NC): Small varieties, mass production.

7. Rich bending shape, with rolling O type, U type, multi-section R type auxiliary cone cylinder device, can roll a certain range of cone cylinder. O-bend: rear bend; U bend: front bend mode; Multi-segment R bending: Combined mode.

Uncoil Leveling Machine

Uncoil Leveling Machine Shearing Machine

Shearing Machine Laser Cutting Machine

Laser Cutting Machine Press Brake Machine

Press Brake Machine Rolling Machine

Rolling Machine Hydraulic press machine

Hydraulic press machine Welding Machine

Welding Machine Robot Arm

Robot Arm