- Overview

- Recommended Products

| Place of Origin: | CHINA |

| Brand Name: | WEILI |

| Certification: | ISO9001 |

| Minimum Order Quantity: | 1 |

| Price: | Depending on the model number |

| Packaging Details: | Wooden box, waterproof |

| Delivery Time: | 20 days |

| Payment Terms: | 30% deposit,pay the 70% balance before delivery |

| Supply Ability: | Advanced manufacturing capabilities for large-scale orders |

Description

1. The two-roller roll forming machine is a novel type of roll forming machinery..Its upper roller is a steel roller, and the lower roller is outsourcing a steel core elastic layer. The plate is placed between the two rollers and adjusts their spacing so that it contacts - pressure - the lowerroller deforms, and the plate subsequently deforms locally, driving the two roller rotations, so that the plate is continuously bent and molded.

2. The machine can be formed at once, the production efficiency is high, the product geometric accuracy is high, surface quality is good, the structure is simple, the number of rollers is least, the operation is easy, and it is easy to achieve the numerical control of the production process.

3. Have a wide range of uses, and is rapidly mass-produced thin ducts, ventilation pipes, chimneys, filters, solar water heaters, automobile exhaust pipes, liquid (gas) tanks, etc.

4. automatic degree of equipment: manual feeding, automatic rolling system, automatic unloading

5. The use of PLC control the whole machine operation, improve the reliability of equipment.

Competitive Advantage

1. Primarily used for forming finished coils on thin sheets (1-3 mm) and is suitable for applications such as water heaters and firefighting equipment, as well as the automotive manufacturing and decoration industries.

2. Can be used as a standalone unit or integrated into production lines.

3. Extremely high production efficiency; each work cycle (completing a single finished product) is completed every 30 seconds.

4. The entire process, from loading the material, aligning it, feeding it into the machine, forming the coil, and dispatching the finished product, is fully automated by computer control. The formed parts have precise roundness, easy operation, reliable accuracy, and high efficiency.

5. The coil is formed in a single operation, completely eliminating any remaining straight edges.

Uncoil Leveling Machine

Uncoil Leveling Machine Shearing Machine

Shearing Machine Laser Cutting Machine

Laser Cutting Machine Press Brake Machine

Press Brake Machine Rolling Machine

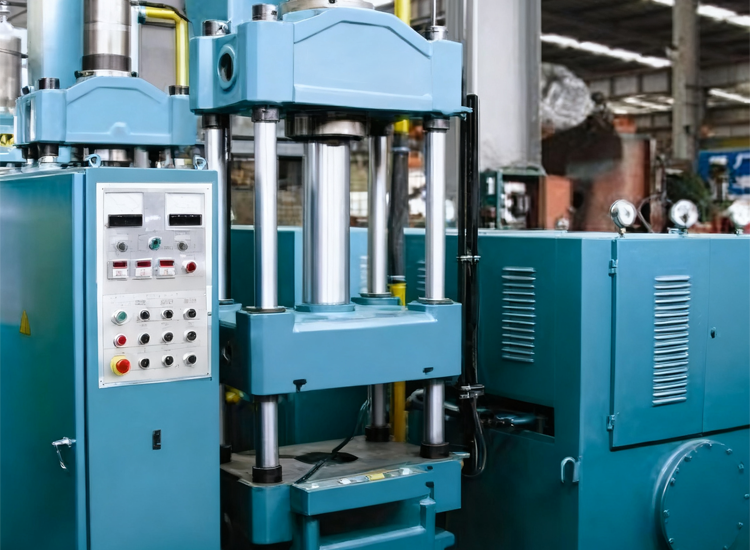

Rolling Machine Hydraulic press machine

Hydraulic press machine Welding Machine

Welding Machine Robot Arm

Robot Arm