- Overview

- Recommended Products

| Place of Origin: | CHINA |

| Brand Name: | WEILI |

| Certification: | ISO9001 |

| Minimum Order Quantity: | 1 |

| Price: | Depending on the model number |

| Packaging Details: | Wooden box, waterproof |

| Delivery Time: | 20 days |

| Payment Terms: | 30% deposit,pay the 70% balance before delivery |

| Supply Ability: | Advanced manufacturing capabilities for large-scale orders |

Description

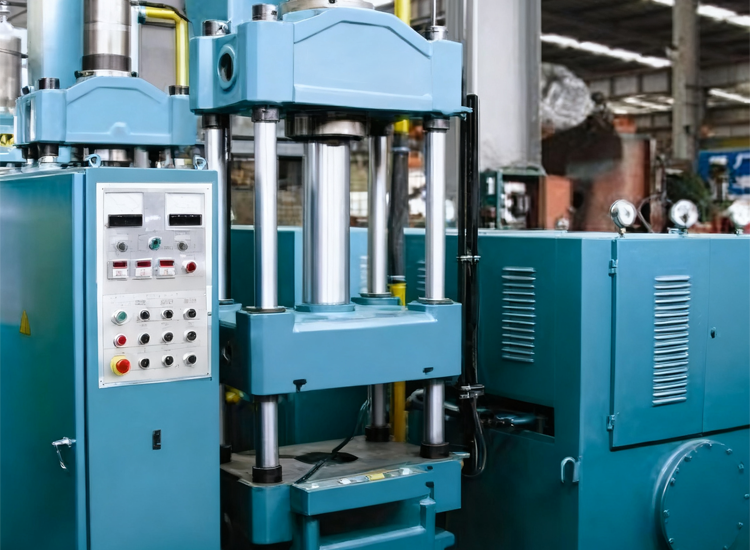

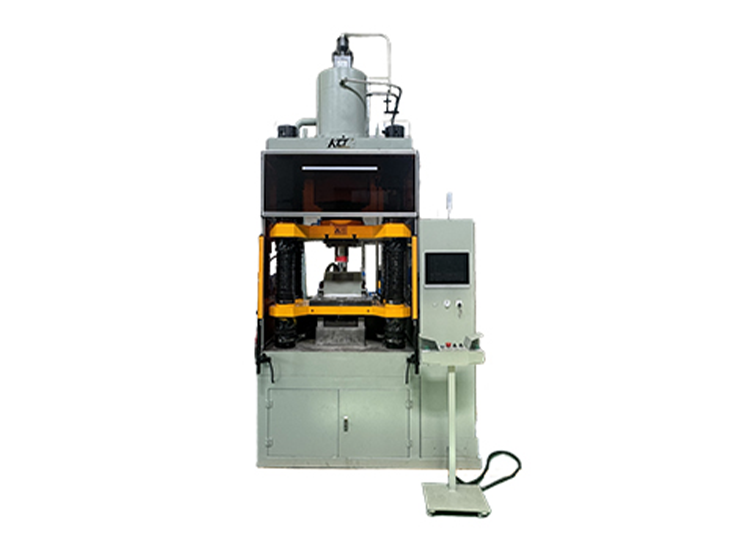

The YH98 series research and assembly hydraulic press is suitable for industries such as aircraft, automobiles, and home appliances. It is particularly useful during the process of remanufacturing, maintenance, and major overhaul of large and medium-sized molds. It can also perform processes such as stretching and dropping material, making it highly versatile. The machine body is composed of a top beam, a slide block, a base, left and right vertical columns, a pull rod, and a lock nut. It employs a pre-stressed combined frame structure, with the top beam, base, and vertical columns forming a combined frame through the pull rod and lock nut. Four-corner, eight-sided guide rails are installed inside the vertical columns to serve as guides for the slide block. The guide rails are made of wear-resistant self-lubricating bearings, offering strong load-bearing capacity, high precision, and good stability. The structural components of the machine body are all made of steel plate welded structures. After welding, they undergo annealing treatment to eliminate internal stresses. The machine body is equipped with hydraulic nut pre-tightening, ensuring good precision retention.

Optional components: 180-degree flip mechanism for the upper mold, movable worktable, grating protection, touchscreen interface, proportional control of pressure, speed, displacement, imported electronic control system, hydraulic system, and sealing components.

YH98 series mold research and fitting hydraulic press application areas: This equipment is mainly suitable for the research and fitting, adjustment, and trial molding of large-scale molds in industries such as automotive and aviation, as well as home appliances. It can also meet the needs of other pressure forming processes.

Competitive Advantage

1. This series of machines can be selected between a four-column model and a frame-based model, depending on user needs.

- Four-column model: Simple structure, cost-effective, and practical.

- Frame-based model: Either a complete or split frame design with 8-sided, right-angle guide rails. Excellent rigidity, high precision, and strong resistance to uneven loads.

2. Utilizing PLC (Programmable Logic Controller) automation, it can perform both point-to-point and semi-automatic operations. Additionally, it can be integrated with external production lines to achieve fully automated functionality.

3. Custom specifications can be tailored according to user requirements. All welded components undergo heat treatment, and the piston rods of the vertical columns are subjected to hardening and electroplating processes.

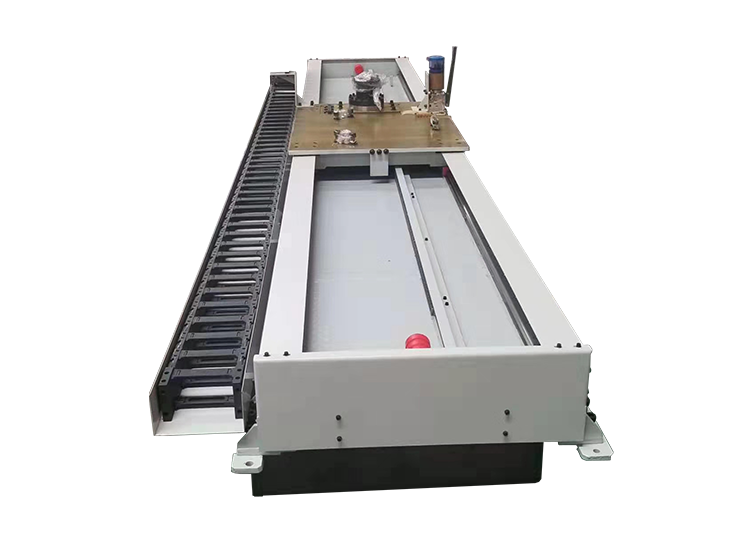

Uncoil Leveling Machine

Uncoil Leveling Machine Shearing Machine

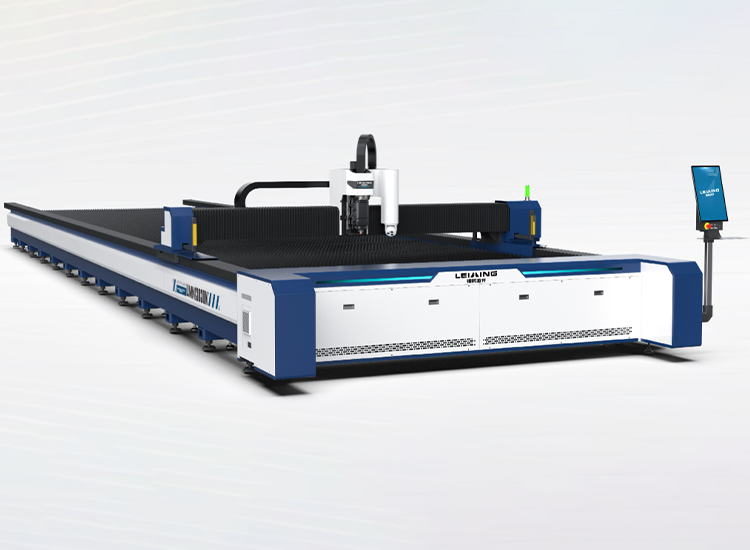

Shearing Machine Laser Cutting Machine

Laser Cutting Machine Press Brake Machine

Press Brake Machine Rolling Machine

Rolling Machine Hydraulic press machine

Hydraulic press machine Welding Machine

Welding Machine Robot Arm

Robot Arm