- Overview

- Recommended Products

| Place of Origin: | CHINA |

| Brand Name: | WEILI |

| Certification: | ISO9001 |

| Minimum Order Quantity: | 1 |

| Price: | Depending on the model number |

| Packaging Details: | Wooden box, waterproof |

| Delivery Time: | 20 days |

| Payment Terms: | 30% deposit,pay the 70% balance before delivery |

| Supply Ability: | Advanced manufacturing capabilities for large-scale orders |

Description

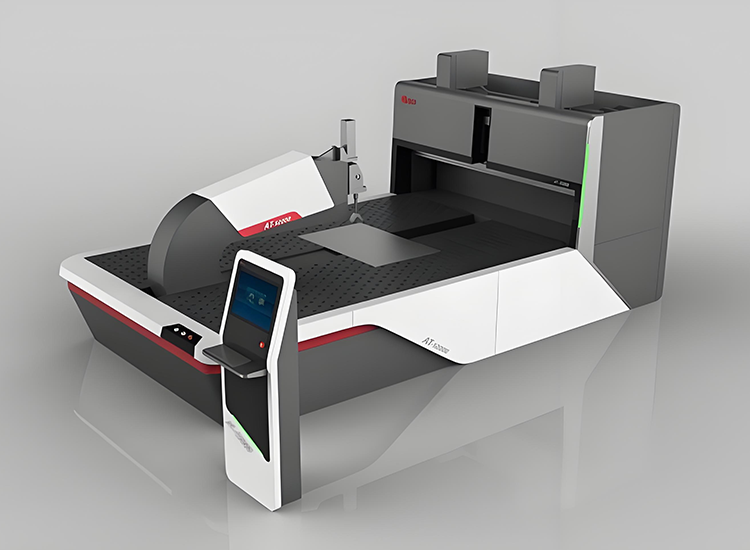

The electronic ceramic powder servo molding machine uses a servo motor to drive a screw rod, which then actuates the upper punch, mother mold, and lower punch to perform high-precision up-and-down movements. The powder is fed into the negative mold through a hopper, feed pipe, and feed shoe, enabling fully automated processes such as powder pressing molding, demolding, picking up the product, and loading it onto a tray. Pressure accuracy: ±1%; displacement accuracy: ±0.01mm; driving method: pure electric, oil-lubricated up, electric down; servo hydraulic.

Magnetic material powder/hard alloy powder/servo forming machine uses a servo motor to drive a screw, which then actuates the upper punch, mother mold, and lower punch to perform high-precision up-and-down movements. The powder is fed into the negative mold through a hopper, pipe, and shoe, enabling fully automated powder pressing, demolding, picking up the powder, and loading it into a tray. The forming speed of the equipment ranges from 1 to 30 revolutions per minute; the pressure accuracy is ±1%; the displacement accuracy is ±0.01 mm; the driving method is pure electric, oil-based electric, and servo hydraulic; the pressure ranges from 20T to 800T; the mold frame structure includes configurations such as one above one, one above two, one above three, two above two, two above three, and two above four; all parameters can be customized as needed.

Driving method: Pure electric, oil-based electric, servo hydraulic.

All parameters can be customized as needed.

Competitive Advantage

1. High precision control The servo pressing machine has a separate servo system and electrical system, which can achieve floating pressing, precisely control pressure and displacement, and achieve high precision molding of fine powder. The molding accuracy can reach less than 0.02 mm, and the repetition accuracy can reach less than 0.005 mm.

2. Flexible scaffold structure The scaffolding structure is diverse, including first and next, first and second, first and third, first and two, first and three, first and four, etc., suitable for complex product suppression with multiple segments and multiple blind pores. The effectiveness is fast, the life span is long, the quality is high, and the suitability is wide.

3. Multiple drive modes The servo pressing machine can adopt a variety of drive modes, such as upper servo hydraulic cylinder drive + lower servo hydraulic drive.Or upstroke AC servo motor + screw direct drive + downstroke AC servo motor + screw direct drive, etc., to ensure accurate control of pressure and displacement to meet different pressing needs.

4. Intelligent automatic molding saves time and effort Fully automatic pollination, Molding, de-molding, picking up materials, packing, etc. Recording and analyzing the product forming process to achieve flexible assembly operations

5. Efficientity and stability Efficientness and stability: the equipment operates stable, easy to operate, and has mechanical limiting devices to ensure the consistency of the product. At the same time, the equipment is simple in structure, easy to maintain, environmentally friendly and energy efficient.

Uncoil Leveling Machine

Uncoil Leveling Machine Shearing Machine

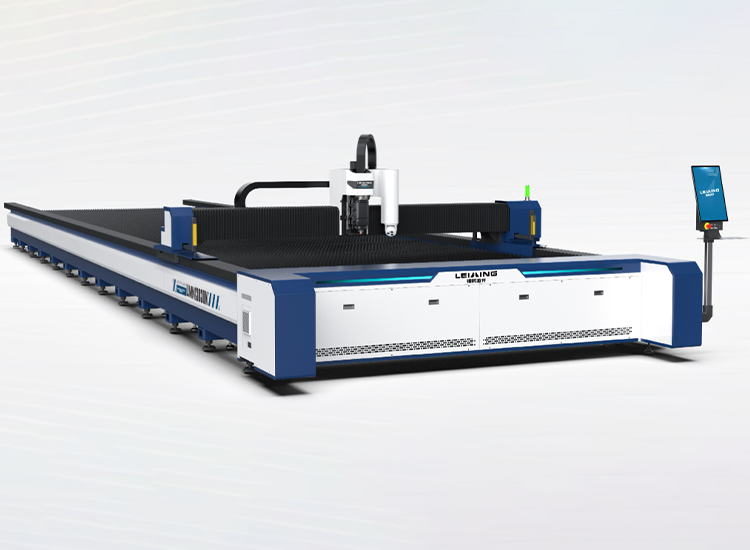

Shearing Machine Laser Cutting Machine

Laser Cutting Machine Press Brake Machine

Press Brake Machine Rolling Machine

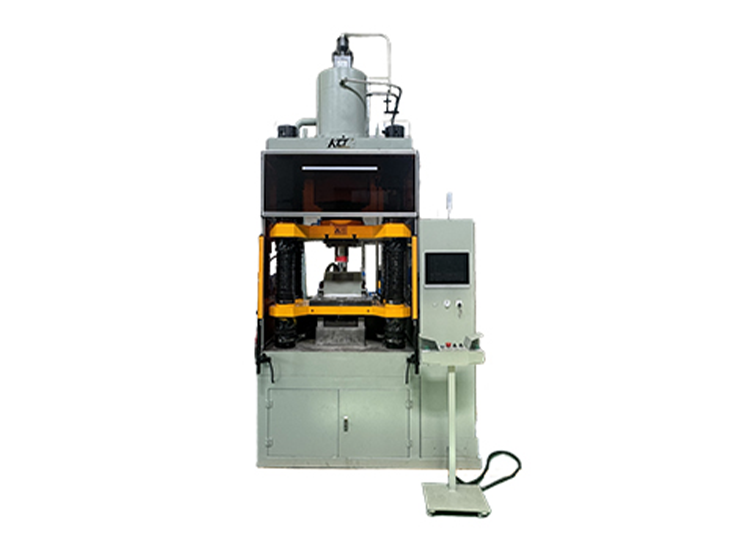

Rolling Machine Hydraulic press machine

Hydraulic press machine Welding Machine

Welding Machine Robot Arm

Robot Arm