- Overview

- Recommended Products

| Place of Origin: | CHINA |

| Brand Name: | WEILI |

| Model Number: | RMW series, HW series,etc. |

| Certification: | ISO9001 |

| Minimum Order Quantity: | 1 |

| Price: | Depending on the model number |

| Packaging Details: | Wooden box, waterproof |

| Delivery Time: | 20 days |

| Payment Terms: | 30% deposit,pay the 70% balance before delivery |

| Supply Ability: | Advanced manufacturing capabilities for large-scale orders |

Description

Laser welding machine is an advanced equipment that utilizes high-energy density laser beams to achieve material fusion, and it is widely used in automobile, electronics, aerospace, and other fields.

Applications

Equipped with a non-teaching welding system, this device boasts a wealth of functions and makes operation both quicker and more convenient, thereby enhancing welding speed and production efficiency.

1. One-click extraction of weld seam: The system automatically identifies and extracts the position and trajectory of the weld seam on the welding workpiece, automatically generating the welding path.

2. Intelligent arc tracking: A closed-loop control technology that real-time detects the position of the weld seam and automatically corrects any deviations. 3. Diverse weld seam forms: Supports multiple layers, arc tracking, intermittent welding, continuous curves, tapered joints, and joints, among other forms.

Specifications

Industrial welding robot with 6 axes

Robot arm length: 2116mm

Minimum sheet thickness: 0.8mm

Maximum sheet thickness: 30mm

Competitive Advantage:

Performance Advantages

The inverter-based welding machine features low spatter, multiple welding modes, and a comprehensive arc welding process package.

1. Suitable for welding both thin and thick plates: Arc welding creates large weld points, making it suitable for both thin and thick plates (0.8-30mm).

2. High welding efficiency: Compared to manual arc welding, robotic arc welding offers rapid start/stop functions and high welding speeds, resulting in a 30% increase in welding efficiency.

3. Consistent and high-quality welds: Robotic arc welding is highly stable and precise, effectively minimizing common issues such as edge defects, burn-through, and excessive heat residue that can occur during manual arc welding. This ensures high-quality welds and consistent results.

Mechanical Advantages

1. Meets the need for high precision welding: The robot has high repeat positioning accuracy, strong rigidity, and a large load capacity, enabling it to perform tasks requiring high precision over an extended period. The interface is user-friendly and easy to learn.

2. CE Certified Arc Welding Machine: The machine features both MIG and MAG models, with various welding modes such as pulse, rapid pulse, deep penetration, and constant pressure. Customized process modules can be developed based on customer needs to achieve low/ultra-low spatter welding. 3. Self-Protection Function of the Welding Gun: The welding gun is equipped with a collision-prevention system, ensuring safety and reliability. This feature prevents potential injuries to the welding gun, workpiece, or personnel due to accidental operation.

4. Flexibility and Adaptability: By attaching a welding platform or adding external axes, it is possible to perform welding on any position of the workpiece. Additionally, it can be used with various fixtures to handle complex welding tasks.

Uncoil Leveling Machine

Uncoil Leveling Machine Shearing Machine

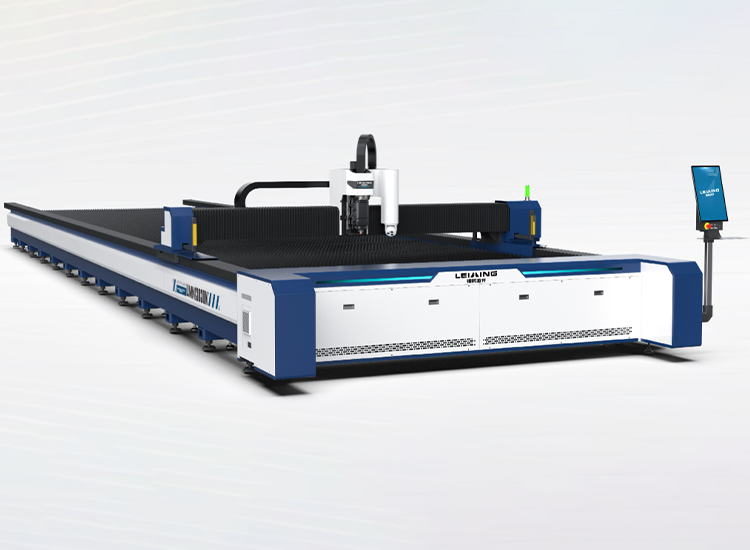

Shearing Machine Laser Cutting Machine

Laser Cutting Machine Press Brake Machine

Press Brake Machine Rolling Machine

Rolling Machine Hydraulic press machine

Hydraulic press machine Welding Machine

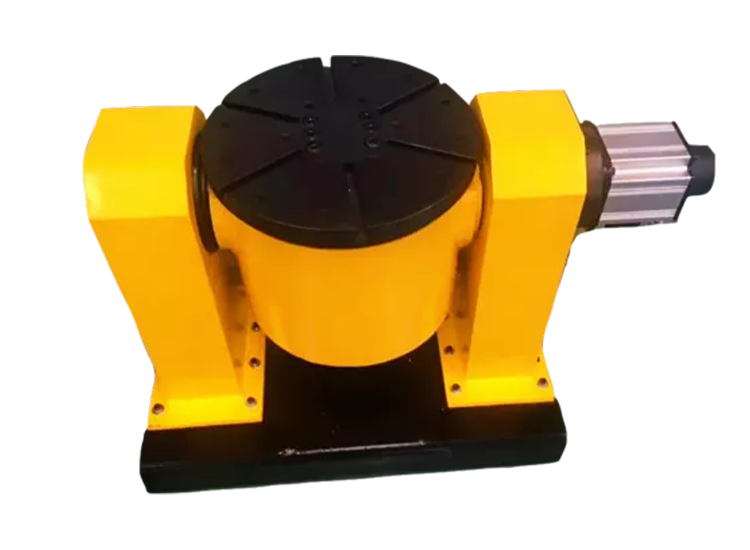

Welding Machine Robot Arm

Robot Arm