- Overview

- Recommended Products

| Place of Origin: | CHINA |

| Brand Name: | WEILI |

| Certification: | ISO9001 |

| Minimum Order Quantity: | 1 |

| Price: | Depending on the model number |

| Packaging Details: | Wooden box, waterproof |

| Delivery Time: | 20 days |

| Payment Terms: | 30% deposit,pay the 70% balance before delivery |

| Supply Ability: | Advanced manufacturing capabilities for large-scale orders |

Description

The structure type of the ship-use three-roller symmetrical roll forming machine is three-roller symmetrical. The upper roller moves vertically up and down at the central symmetrical position between the two lower rollers. This movement is achieved through the hydraulic oil inside the hydraulic cylinder, which acts on the piston rod, making it a hydraulic transmission system. A specially designed reducer drives the two lower rollers, which are equipped with full rolling bearings, to rotate, providing the necessary torque for forming the sheet material. Multiple sets of support rollers are located at the bottom of the lower rollers to enhance their rigidity and allow for vertical adjustment. A rigid beam is situated above the upper roller, and multiple sets of support rollers are placed between the beam and the upper roller to further enhance the rigidity of the upper roller. This machine is suitable for forming extremely wide, curved parts.

Competitive Advantage

The design is fully enclosed to prevent dust from entering.

This ship-grade three-roller symmetrical roll-forming machine has resolved the issue of oil leakage commonly found in domestic three-roller roll-forming machines, with an overall appearance that meets international standards.

It is easy to maintain and has high efficiency, a long lifespan, and excellent environmental performance.

1. The structure is made of fully steel welded components, providing strong rigidity to the equipment. Optimized design calculations were conducted using computer finite element analysis.

2. Both ends of the axis rollers are equipped with adjustable-clearance spherical bearings.

3. The axis rollers are precision-machined from medium-carbon steel after forging and quenching treatment.

4. The two lower rollers of the roll-forming machine have support rollers, which improves the precision of the rolled workpiece and enhances the overall performance of the machine.

5. It employs centralized electrical control, making operation simple and convenient.

6. The control panel is designed with a user-friendly and intuitive interface for easy operation.

7. A centralized lubrication system is integrated.

Uncoil Leveling Machine

Uncoil Leveling Machine Shearing Machine

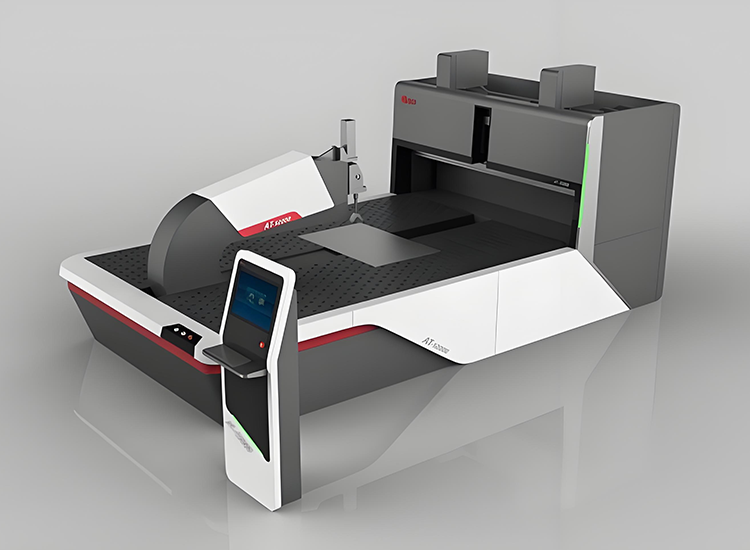

Shearing Machine Laser Cutting Machine

Laser Cutting Machine Press Brake Machine

Press Brake Machine Rolling Machine

Rolling Machine Hydraulic press machine

Hydraulic press machine Welding Machine

Welding Machine Robot Arm

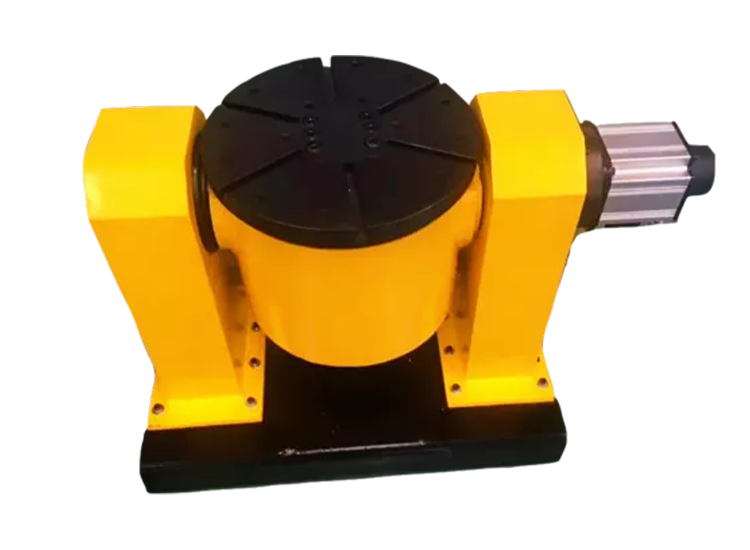

Robot Arm