- Overview

- Recommended Products

| Place of Origin: | CHINA |

| Brand Name: | WEILI |

| Model Number: | Model 1600, Model 1800, etc. |

| Certification: | ISO9001 |

| Minimum Order Quantity: | 1 |

| Price: | Depending on the model number |

| Packaging Details: | Wooden box, waterproof |

| Delivery Time: | 20 days |

| Payment Terms: | 30% deposit,pay the 70% balance before delivery |

| Supply Ability: | Advanced manufacturing capabilities for large-scale orders |

● High degree of automation, simple operation, and reliability.

● Interchangeable positioning of the slitting machine, high work efficiency.

● Fast production line speed, self-matching of machine speeds.

Description

This production line consists of a feeding trolley, a coil opening device, a feeding device, a disc blade longitudinal slitting machine, a damping pre-separation unit, a winding unit, a unloading trolley, and a control system. Its main function is to cut a wide metal coil into multiple strips of desired width along the length direction. It is used to prepare raw materials for processes such as rolling, punching, cold bending, and stamping. By adjusting the distance between the upper and lower knife shafts, it can accommodate different thickness sheets. Replacing different specifications of blade spacers and spacers allows for the cutting of strips of varying widths.

Specifications

| Model Type | 1600 Type | 1800 Type | 2000 Type | 2200 Type |

| Raw Coil Material | Hot-rolled pickled steel plate, hot-rolled steel plate, etc. | |||

| Material Thickness | 0.8mm - 6.0mm | 0.8mm - 6.0mm | 2.0mm - 12.0mm | 3.0mm - 16.0mm |

| Material Width | 1600mm (MAX) | 1800mm (MAX) | 2000mm (MAX) | 2200mm (MAX) |

| Coil Weight | 30ton (MAX) | 30ton (MAX) | 30ton (MAX) | 30ton (MAX) |

| Width Precision | ±0.15mm | ±0.15mm | ±0.2mm | ±0.3mm |

| Unit Speed | 120m/min (MAX) | 120m/min (MAX) | 80m/min (MAX) | 60m/min (MAX) |

| Parameter/Model | Processing Plate Thickness (mm) | Processing Plate Width (mm) | Longitudinal Shearing Strips | Longitudinal Shearing Speed (m/min) | Uncoiling Weight (ton) | Remarks |

| LZCN-1x350 | 0.1 - 1 | 80 - 350 | 8 - 30 | 50 - 100 | 3 | Technical parameters and equipment configuration can be determined according to customer needs |

| LZCN-2x350 | 0.2 - 2 | 80 - 350 | 6 - 30 | 50 - 150 | 3 | |

| LZCN-2x450 | 0.2 - 2 | 80 - 450 | 6 - 30 | 50 - 150 | 5 | |

| LZCN-2x650 | 0.2 - 2 | 80 - 650 | 6 - 30 | 50 - 150 | 7 | |

| LZCN-2x800 | 0.2 - 2 | 80 - 800 | 6 - 30 | 50 - 150 | 7 | |

| LZCN-1x1300 | 0.1 - 1 | 500 - 1300 | 12 - 30 | 50 - 200 | 7/15 | |

| LZCN-2x1600 | 0.3 - 2 | 500 - 1600 | 12 - 30 | 50 - 200 | 7/15 | |

| LZCN-3x1600 | 0.3 - 3 | 500 - 1600 | 8 - 30 | 50 - 180 | 15 | |

| LZCN-3x1800 | 0.3 - 3 | 900 - 1800 | 8 - 30 | 50 - 180 | 20 | |

| LZCN-4x1600 | 1 - 4 | 900 - 1600 | 6 - 30 | 50 - 120 | 20 | |

| LZCN-6x1600 | 1 - 6 | 900 - 1600 | 6 - 30 | 30 - 80 | 30 | |

| LZCN-12x1600 | 2 - 12 | 900 - 1600 | 5 - 30 | 20 - 50 | 30 |

Uncoil Leveling Machine

Uncoil Leveling Machine Shearing Machine

Shearing Machine Laser Cutting Machine

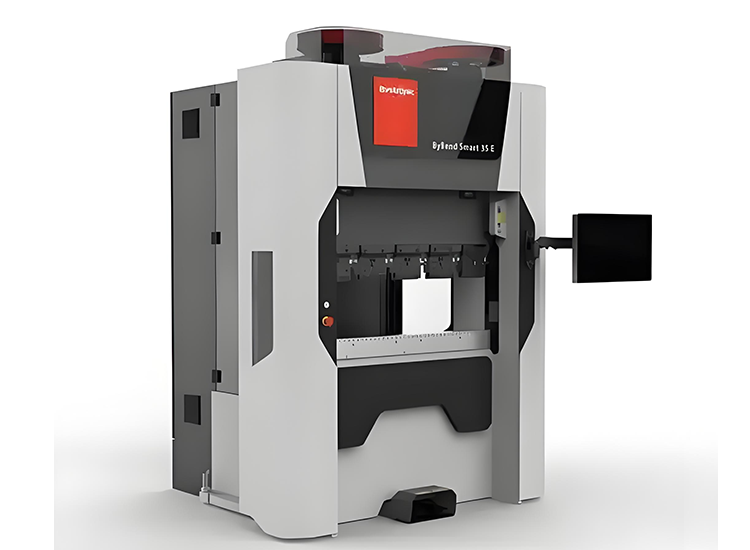

Laser Cutting Machine Press Brake Machine

Press Brake Machine Rolling Machine

Rolling Machine Hydraulic press machine

Hydraulic press machine Welding Machine

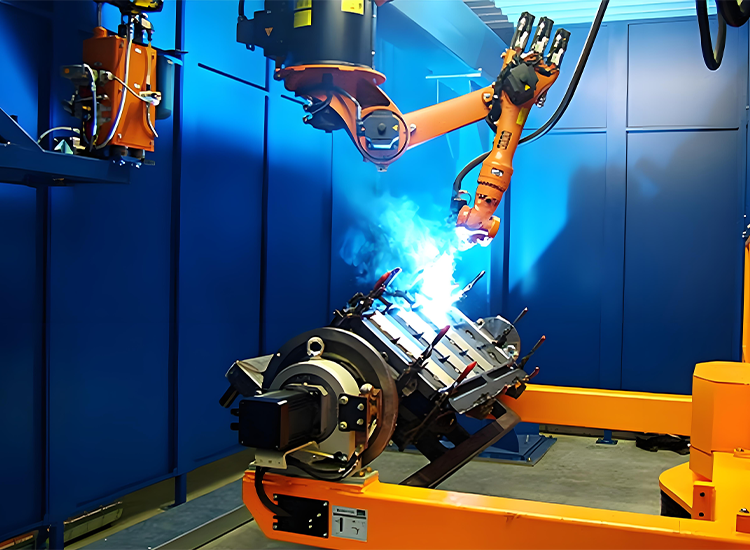

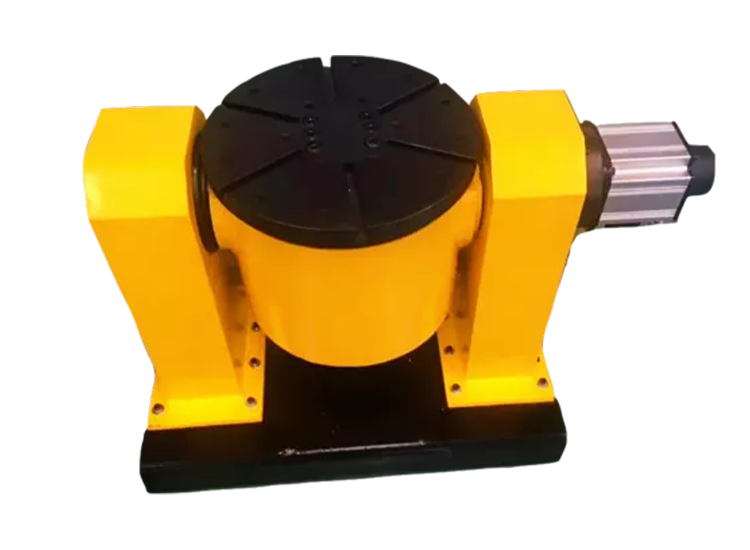

Welding Machine Robot Arm

Robot Arm