- Overview

- Recommended Products

| Place of Origin: | CHINA |

| Brand Name: | WEILI |

| Certification: | ISO9001 |

| Minimum Order Quantity: | 1 |

| Price: | Depending on the model number |

| Packaging Details: | Wooden box, waterproof |

| Delivery Time: | 20 days |

| Payment Terms: | 30% deposit,pay the 70% balance before delivery |

| Supply Ability: | Advanced manufacturing capabilities for large-scale orders |

Description

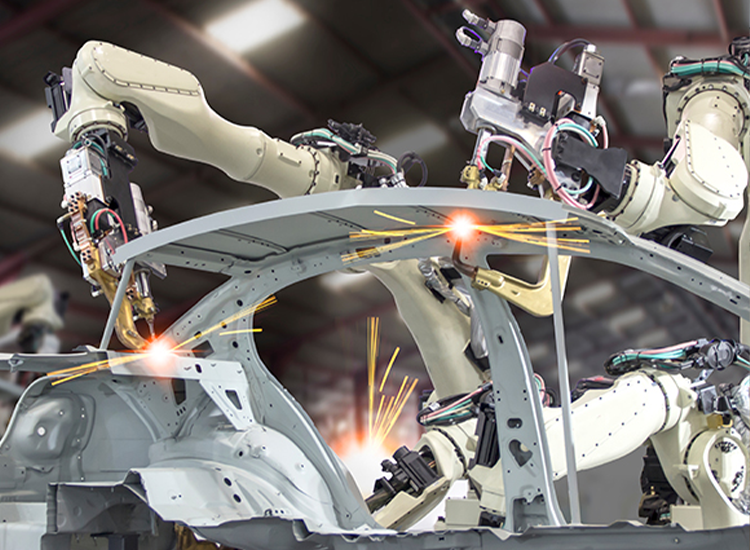

WEILI·Welding Automation Production Line Possesses Comprehensive Technical Capabilities in Software and Hardware R&D, Design, and Integration

The Characteristics of the Production Line Overview ·

Welding automation equipment typically integrates various technologies such as welding processes, automatic control, and precision mechanical design and manufacturing. With the continuous development and widespread application of automation, intelligence, and digitalization technologies, welding automation is evolving from single-machine welding automation equipment to welding automation production lines and digital welding workshops. ·

To establish a smart welding processing method and process scheme that minimizes or eliminates the need for human involvement in the welding process, it integrates the configuration of welding mechanical equipment and control systems. By utilizing welding mechanical devices to perform the welding process, it aims to further improve welding quality, increase production volume, reduce costs, lower labor intensity, and ensure production safety.

Competitive Advantage

1. Reducing the dependence on personnel

Nowadays, enterprises are difficult to recruit, train and manage. In the past, traditionally, one person, one machine, and personnel need to move materials, Grabbing welding, placing containers, and different processes also need to be switched between different workplaces, which consumes a lot of labor, while the fully automatic welding station integrates multiple processes together, completes the original large number of hand-held jobs through a robot, and only requires external filling personnel to operate, saving a lot more labor.

2. Improved efficiency

The fully automatic welding workstation matches the rhythm of the different processes optimally, increases the equipment starting rate and reduces the material time that was previously handled by a single person on a single station, and the operating time of the whole station can reach 24H, doubling the capacity.

3. The improvement of quality

Through the positioning of the automatic fixture for the entire site, the state of the workpiece is ensured to be consistent. The welding data is matched, stored, and uploaded automatically, allowing the process engineers and quality engineers to understand the welding parameters of all products in the first instance, optimize them, and make judgments. This ensures that the welding process truly forms a closed loop, guaranteeing that the output products are of satisfactory quality.

4. The safety assurance

Enterprise production is most concerned about the occurrence of work-related injuries, and the fully automated welding workstation employs a fully enclosed protective system. Workers only add materials externally and do not participate in the normal welding process, thereby avoiding the risk of injuries such as finger crush or splash injuries caused by manual operation. This fully meets the requirement of zero work-related injuries.

5. Space saving

Most enterprises are quite cautious when it comes to utilizing the space in their workshops, as the consumption of workshop space directly translates to the cost of rent, the consumption of pipelines, and the consumption of kinetic energy. Fully automated welding workstations are designed with a focus on efficiency, with the goal that all movements should be as brief as possible. This results in a compact layout for the entire station, which meets the demand of enterprises for high space utilization.

Uncoil Leveling Machine

Uncoil Leveling Machine Shearing Machine

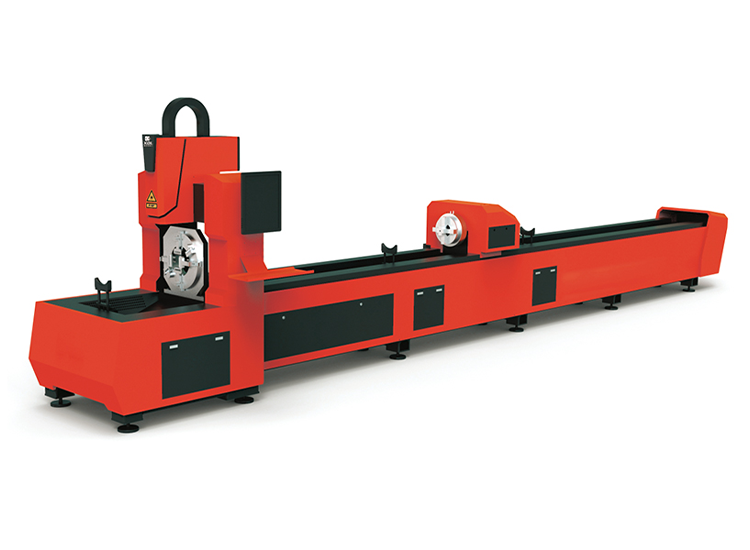

Shearing Machine Laser Cutting Machine

Laser Cutting Machine Press Brake Machine

Press Brake Machine Rolling Machine

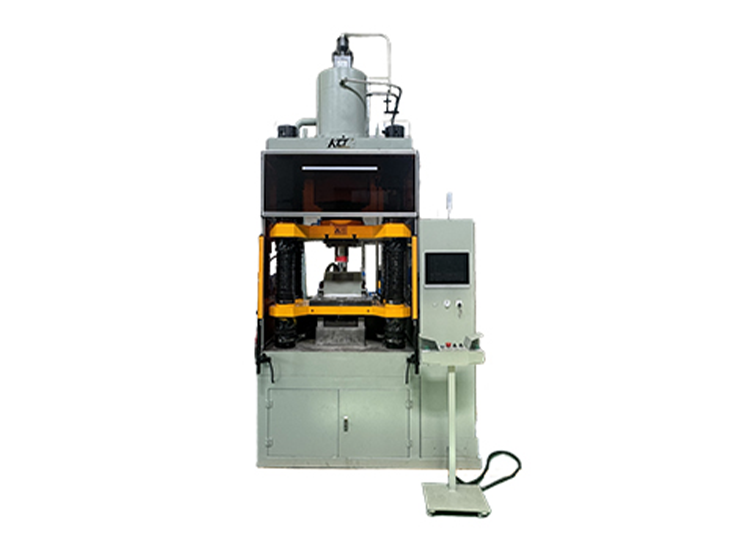

Rolling Machine Hydraulic press machine

Hydraulic press machine Welding Machine

Welding Machine Robot Arm

Robot Arm