- Overview

- Recommended Products

| Place of Origin: | CHINA |

| Brand Name: | WEILI |

| Certification: | ISO9001 |

| Minimum Order Quantity: | 1 |

| Price: | Depending on the model number |

| Packaging Details: | Wooden box, waterproof |

| Delivery Time: | 20 days |

| Payment Terms: | 30% deposit,pay the 70% balance before delivery |

| Supply Ability: | Advanced manufacturing capabilities for large-scale orders |

Description

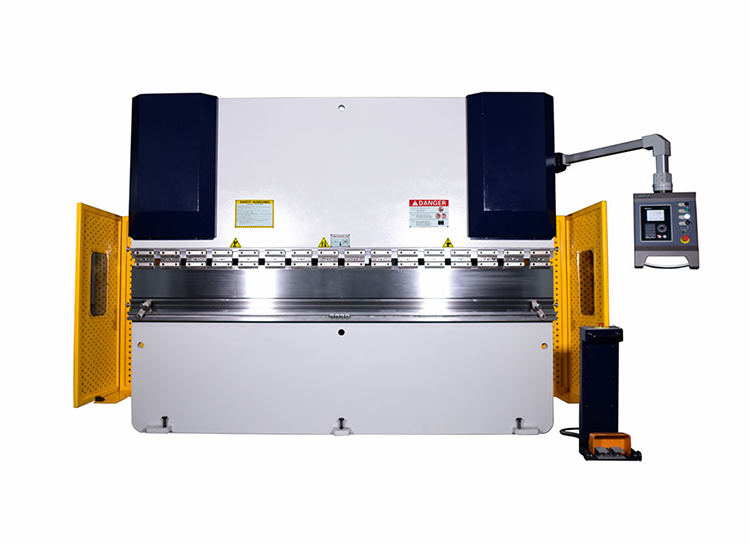

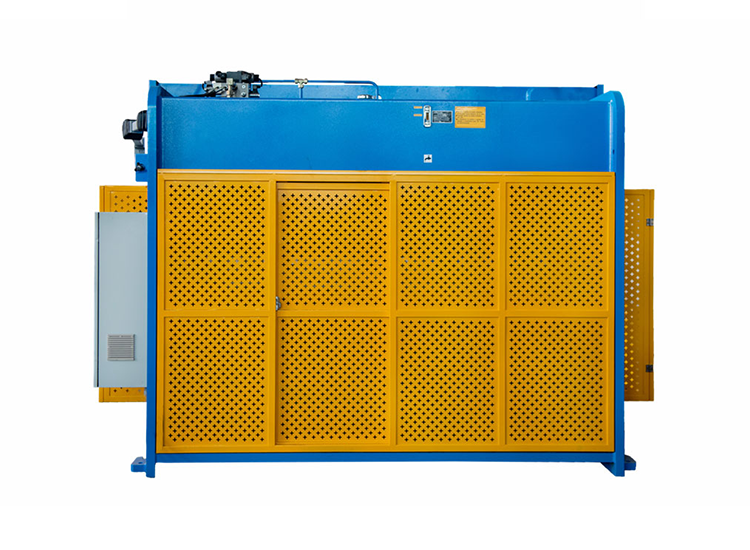

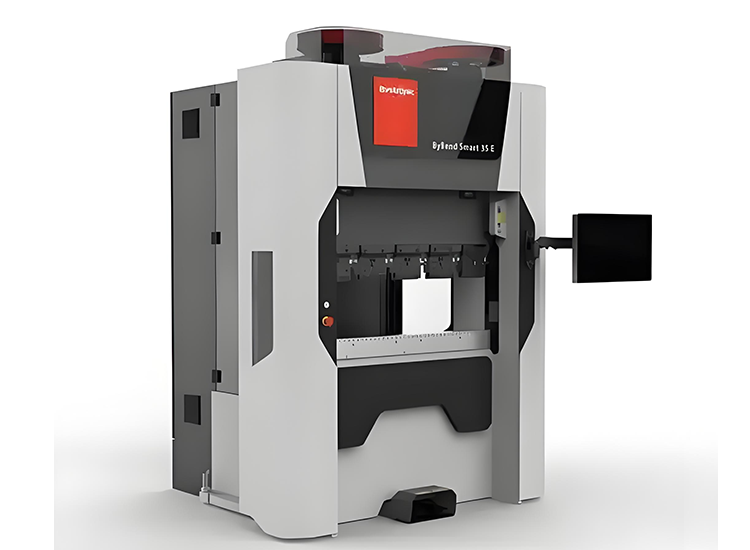

The entire structure is made of high-strength steel and undergoes welding, followed by heat treatment to eliminate internal stresses, resulting in excellent rigidity and stability. The twisting axis is synchronized with a mechanical stop block for balanced operation, ensuring high precision. An integrated hydraulic system powers the slide block, allowing for a wide speed adjustment range and smooth, reliable operation. The bending angle and rear stop travel can be adjusted using CNC technology. The slide block travel adjustment mechanism is separate from the hydraulic cylinder assembly, enhancing sealing performance. The upper mold is equipped with a system for compensating for the deflection of the slider. Bending machines with a capacity of 250 tons or more utilize a system for compensating for the curvature of the lower worktable.

Specifications

Comprehensive specifications and customization options available. Machines range from 30-3000T in capacity, with working lengths of 1.5-12M. Models include electro-hydraulic synchronization, oil-electric hybrid, and CNC-controlled twisting axis bending machines. Various auxiliary devices can also be customized.

Competitive Advantage

· Complete specifications, support customization: 30-3000 T, working length 1.5-12M, electro-hydraulic synchronous type, oil-electric hybrid type, CNC torsion shaft type bending machine, all kinds of auxiliary devices can be customized.

· Mold customization, mature process: Molds are customized by renowned Chinese manufacturers according to requirements, carry out material and hardness testing, and the process is mature to ensure quality.

· Skilled and controllable delivery: semi-finished products planned production, modular design, ERP management, order production and planned production parallel, greatly reducing the lead time;Modular design of components, versatility, conventional, general parts sufficient, general products 3-30 days delivery, custom products 40 days delivery.

· Once installed, electricity is available: Before leaving the factory, the machine tool has been commissioned to a good condition and after 8 hours of test drive, after training, the user can use it normally.

· Adapt to the market and respond quickly: outlets are configured in major regions across the country with dedicated customer service staff, respond within 4 hours, and reach the user site within 24 hours.

· Quality commitment, customer reassurance: a one-year warranty, implementation in accordance with the national "three packages" regulations, and meticulous one-stop service to solve customers' concerns.

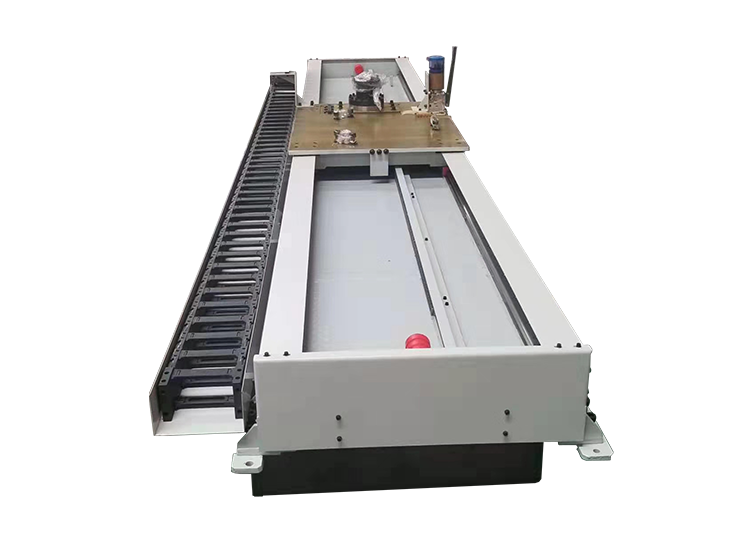

Uncoil Leveling Machine

Uncoil Leveling Machine Shearing Machine

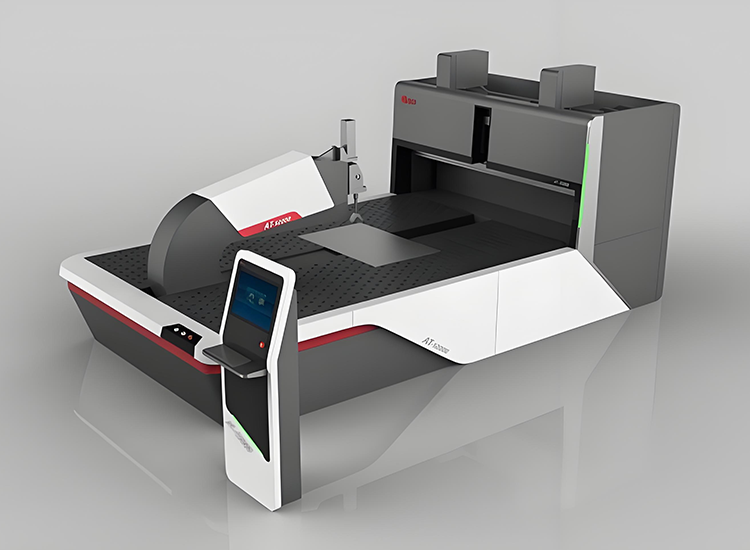

Shearing Machine Laser Cutting Machine

Laser Cutting Machine Press Brake Machine

Press Brake Machine Rolling Machine

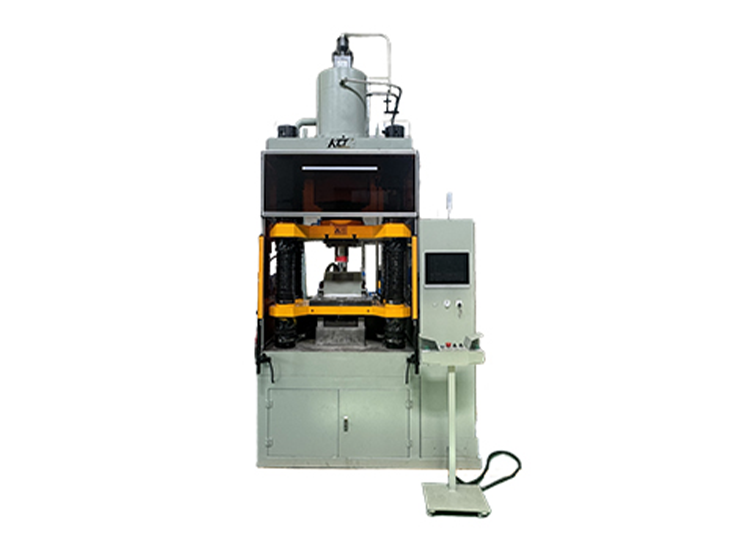

Rolling Machine Hydraulic press machine

Hydraulic press machine Welding Machine

Welding Machine Robot Arm

Robot Arm