- Overview

- Recommended Products

| Place of Origin: | CHINA |

| Brand Name: | WEILI |

| Certification: | ISO9001 |

| Minimum Order Quantity: | 1 |

| Price: | Depending on the model number |

| Packaging Details: | Wooden box, waterproof |

| Delivery Time: | 20 days |

| Payment Terms: | 30% deposit,pay the 70% balance before delivery |

| Supply Ability: | Advanced manufacturing capabilities for large-scale orders |

Description

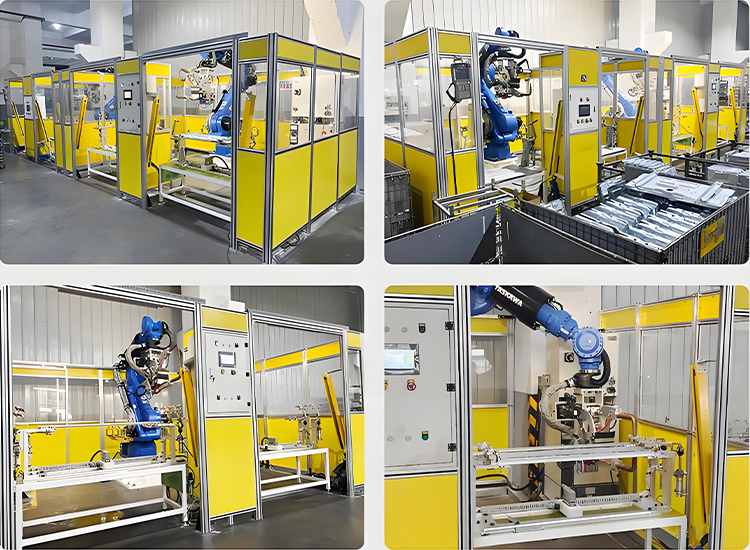

Point welding workstation is the core equipment for high-precision and high-efficiency welding in intelligent manufacturing, widely used in automotive, home appliances, sheet metal processing and other fields.

1. Robot system: six-axis industrial robot, responsible for welding gun movement, trajectory control and workpiece handling, with servo or pneumatic welding clamp to achieve accurate positioning.

2. Welding system: including medium frequency reverse power supply, controller and welding pliers (C / X design), through closed-loop current control and pressure monitoring to ensure the consistency of the solder joints.

3. Clamp systems: customise rigid clamps or flexible modules to ensure the positioning accuracy and geometric stability of the workpiece.

4. Control system: PLC, HMI and other modules cooperate to manage robot action, welding parameters and safety protection.

5. Monitoring System: Integrates visual inspection, grating protection, and AI algorithms to monitor weld quality in real time and alert for any anomalies.

Competitive Advantage

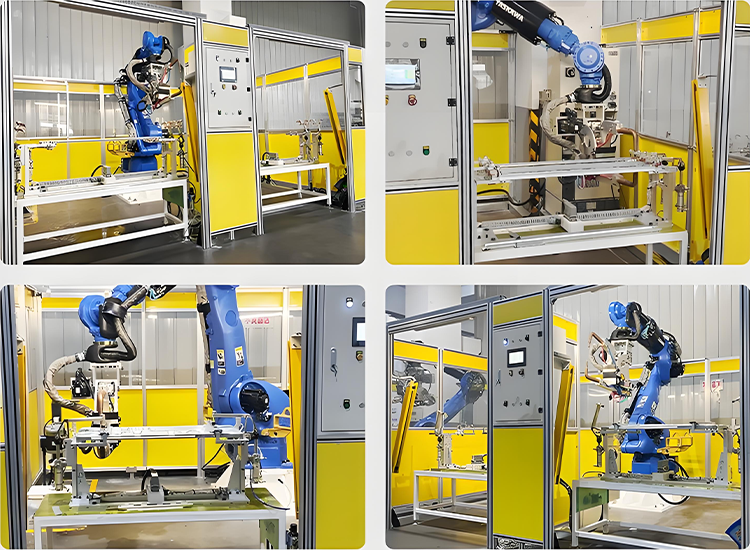

◆ High-speed welding efficiency: By utilizing the synergy of two robots, a turntable-style layout, or automated loading and unloading, the welding cycle can be controlled to 2-4 seconds per spot.

◆ Versatility with various materials: Supports welding of dissimilar materials such as high-strength steel and aluminum alloys. The process is optimized through a parameter database and servo pressure compensation technology.

◆ Intelligent management: Realtime data collection of parameters such as current and voltage, combined with AI algorithms for defect identification and full-lifecycle traceability.

◆ Safety protection: Equipped with devices such as light grids and safety light curtains to ensure the safety of the operators.

Uncoil Leveling Machine

Uncoil Leveling Machine Shearing Machine

Shearing Machine Laser Cutting Machine

Laser Cutting Machine Press Brake Machine

Press Brake Machine Rolling Machine

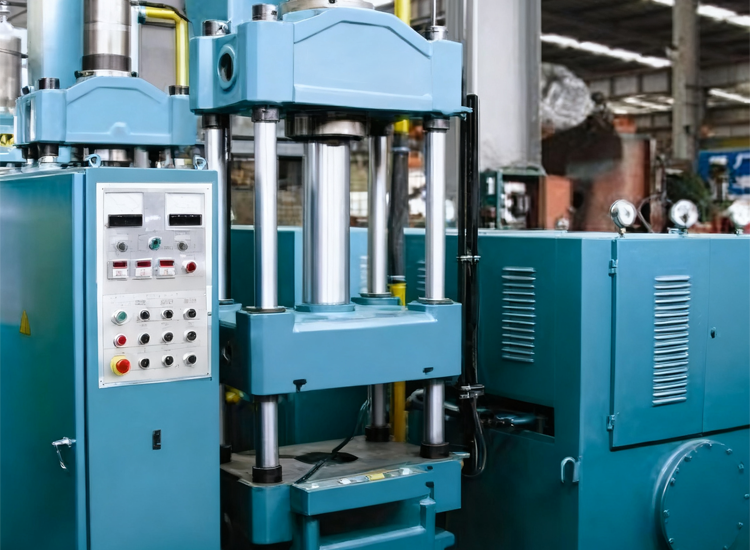

Rolling Machine Hydraulic press machine

Hydraulic press machine Welding Machine

Welding Machine Robot Arm

Robot Arm