- Overview

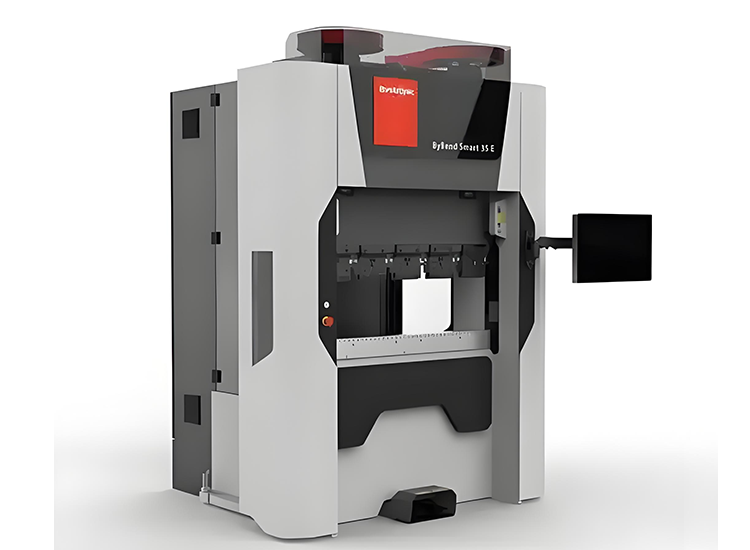

- Recommended Products

| Place of Origin: | CHINA |

| Brand Name: | WEILI |

| Certification: | ISO9001 |

| Minimum Order Quantity: | 1 |

| Price: | Depending on the model number |

| Packaging Details: | Wooden box, waterproof |

| Delivery Time: | 20 days |

| Payment Terms: | 30% deposit,pay the 70% balance before delivery |

| Supply Ability: | Advanced manufacturing capabilities for large-scale orders |

Description

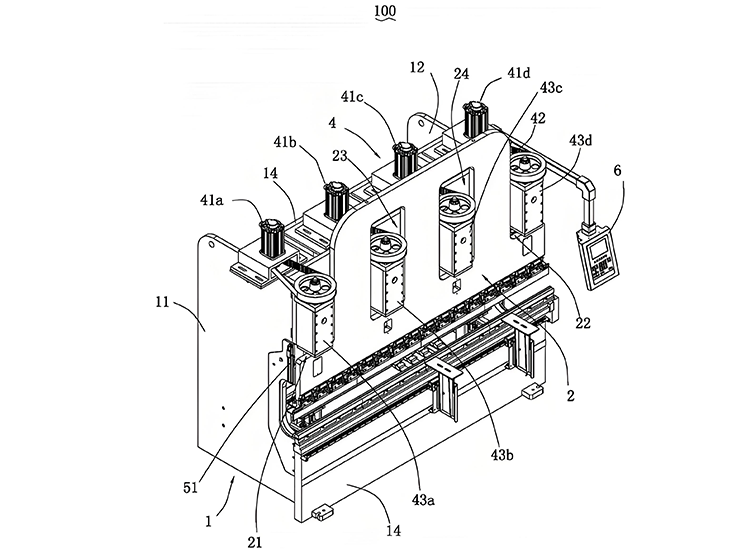

The machine is mainly composed of frame, slider, back stop structure, control system and mold, etc.

(1) Frame: Adopt all-steel welding structure, have enough intensity and rigidity, and carry on the real load condition simulation through finite element analysis, to achieve the required load condition. After the welding, a fire retreat treatment is used to eliminate the residual stress of the welding of the rack.

(2) Sliding blocks: This machine uses a sliding block structure guided by a biased axis, and the overall structure is simple, making it easy to debug and repair.

(3) Control system: the use of NCmax CNC bending system, this system self-developed, flexible operation, simple, It does not require a skilled operator to operate, the programming is simple and quick, no pre-input of mold data is required to process, and the data modification and execution are in the same picture, saving time and simplifying operation. Each axis uses relative position to record the starting point, eliminating the trouble of starting the reset.

(4) Mold: This part consists of two parts: the upper mold component and the lower mold component. The upper mold is installed on the slider and fixed by the splint. The lower mold can be used in various forms such as single V, double V and multi-V. The mold can be segmented or customized according to the requirements of users.

Specifications

| Serial Number | Name | Unit | EP12-600S | EP18/800S | EP30/1250S | EP40/1600S | EP50/2000S |

| 1 | Machine Tool Nominal Pressure | T | 12 | 18 | 30 | 40 | 50 |

| 2 | Worktable | mm | 600 | 800 | 1250 | 1600 | 2000 |

| 3 | Distance Between Columns | mm | 520 | 720 | 1160 | 1510 | 1900 |

| 4 | Throat Depth | mm | 200 | 250 | 300 | 300 | 350 |

| 5 | Slide Stroke | mm | 120 | 120 | 150 | 150 | 150 |

| 6 | Maximum Opening Height | mm | 450 | 420 | 450 | 470 | 480 |

| 7 | Rear Gauge Stroke | mm | 200 | 350 | 500 | 500 | 500 |

| 8 | Maximum Slide Speed | mm/s | 200 | 200 | 200 | 200 | 200 |

| 9 | Main Motor Power | KW | 3.0×2 | 5.5×2 | 7.0×2 | 7.5×2 | 15×2 |

| 11 | Number of Axes | Axis | 4(Y1,Y2,X,R) | 4(Y1,Y2,X,R) | 4(Y1,Y2,X,R) | 4(Y1,Y2,X,R) | 4(Y1,Y2,X,R) |

| 12 | Overall Dimensions (Length×Width×Height) | mm | 1000×970×2100 | 1000×970×2100 | 1400×1200×220 | 1750×1200×220 | 2100×1200×220 |

| 13 | Machine Tool Weight | kg | 1250 | 1800 | 2350 | 3000 | 4200 |

Competitive Advantage

1.Stable and durable: All components, including the imported servo motors, ensure the precision and stability of the machinery, making it highly durable.

2.High precision and long lifespan: Both the linear rail and the lead screw are made from imported C5-grade components, offering high precision, excellent performance, and a long lifespan. The minimum setting unit for the Y-axis movement is 0.005mm.

3.Energy Conservation and Electricity Saving: The difference in electricity usage between a fully electric servo bending machine and an electro-hydraulic servo bending machine is similar to the difference between a variable-frequency air conditioner and a regular air conditioner. A fully electric servo bending machine can automatically output the appropriate amount of power based on the working conditions, and when not in use, it consumes less than 0.5 kW of electricity, making it more energy-efficient.

4.Eco-friendly: No need to use or replace hydraulic oil, thereby preventing the pollution of the environment caused by discarded hydraulic oil.

Uncoil Leveling Machine

Uncoil Leveling Machine Shearing Machine

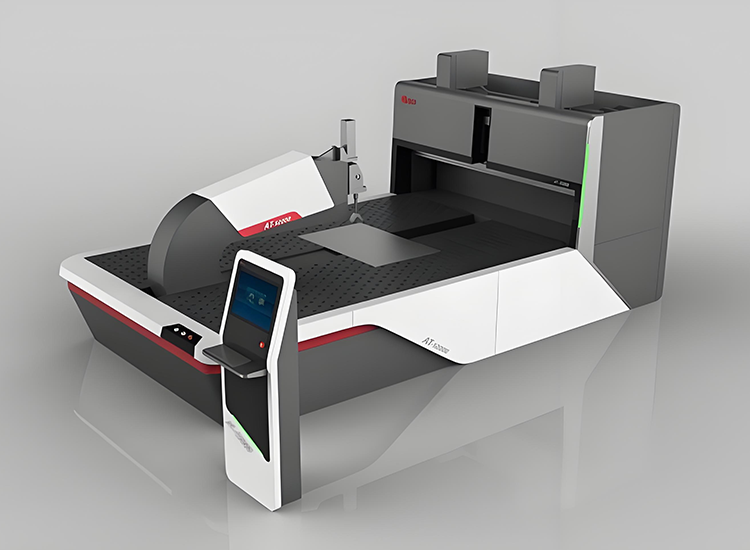

Shearing Machine Laser Cutting Machine

Laser Cutting Machine Press Brake Machine

Press Brake Machine Rolling Machine

Rolling Machine Hydraulic press machine

Hydraulic press machine Welding Machine

Welding Machine Robot Arm

Robot Arm