- Overview

- Recommended Products

| Place of Origin: | CHINA |

| Brand Name: | WEILI |

| Certification: | ISO9001 |

| Minimum Order Quantity: | 1 |

| Price: | Depending on the model number |

| Packaging Details: | Wooden box, waterproof |

| Delivery Time: | 20 days |

| Payment Terms: | 30% deposit,pay the 70% balance before delivery |

| Supply Ability: | Advanced manufacturing capabilities for large-scale orders |

Description

The free forging hydraulic press, also known as the forging hydraulic press, is a machine specifically designed for the free forging process. It utilizes Pascal's law to transmit energy through liquid pressure, enabling it to meet various forging requirements. During operation, the upper and lower anvils of the machine work in conjunction with simple general-purpose tools to cause the steel ingot or billet to undergo plastic deformation under the immense pressure of the pressure cylinder, thus creating forged parts that conform to specific shapes and sizes. The specifications of hydraulic presses are typically measured in terms of nominal working force (in units of MN). In the past, forging often involved the use of water-pressure machines; however, they have gradually been replaced by oil-pressure machines.

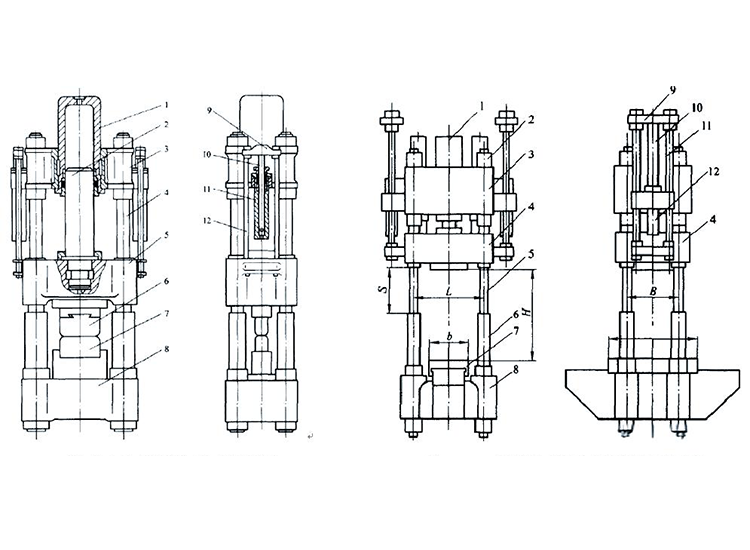

Hydraulic machines usually consist of three core parts: the body (that is, the main), the power system, and the hydraulic control system. Among them, the hydraulic machine itself is the basis of the entire machine, and its structure forms are various, but the three-beam and four-pillar motion form is the most common one. Take the forging hydraulic presses as an example, and a brief diagram of their structure is shown in the diagram. The machine uses upper beams, lower beams, four columns and 16 internal and external nuts to create a closed framework that is responsible for carrying the load at work. The work tank is fixed to the upper beams and is fitted with a working cylinder which is connected to the moving beams. The moving beams are guided by the four columns, and they can be repeatedly moved between the upper and lower beams. Typically, the lower surface of the moving beams is fixed to the upper bracket (i.e. the upper mold), while the lower bracket (ie. the lower mold) is fixed on the workbench on the lower beams. When the high-pressure liquid enters the work tank, it will generate a huge pressure on the work plug, which will push the work plug and the moving beams and the upper chisel downward, causing the workpiece to deform plastically between the upper and lower chisel. During this process, a low pressure liquid is entered into the return tank and the working liquid is discharged. The return tank is fixed to the lower beams, and the return plug is connected to the moving beams. During the return trip, the working tank enters the low pressure liquid, and the high pressure liquid enters the return tank, driving the upward motion of the return plug, thereby driving the active beams back to the original position, completing a complete working cycle.

Uncoil Leveling Machine

Uncoil Leveling Machine Shearing Machine

Shearing Machine Laser Cutting Machine

Laser Cutting Machine Press Brake Machine

Press Brake Machine Rolling Machine

Rolling Machine Hydraulic press machine

Hydraulic press machine Welding Machine

Welding Machine Robot Arm

Robot Arm