- Overview

- Recommended Products

| Place of Origin: | CHINA |

| Brand Name: | WEILI |

| Certification: | ISO9001 |

| Minimum Order Quantity: | 1 |

| Price: | Depending on the model number |

| Packaging Details: | Wooden box, waterproof |

| Delivery Time: | 20 days |

| Payment Terms: | 30% deposit,pay the 70% balance before delivery |

| Supply Ability: | Advanced manufacturing capabilities for large-scale orders |

Description

The electro-hydraulic servo CNC bending machine, also known as the electro-hydraulic valve-controlled servo bending machine, is a CNC bending equipment that employs electro-hydraulic servo control technology. This device originated in the 1970s, with the first application of a CNC system in 1970 and the introduction of an electro-hydraulic servo system in 1978. In 1998, real-time compensation technology was developed.Its core technology consists of a feedback control system composed of an electrical signal processing device and a hydraulic power mechanism, which integrates the technical advantages of both electrical and hydraulic systems.The equipment features a synchronized control design for the two main hydraulic cylinders on both sides.

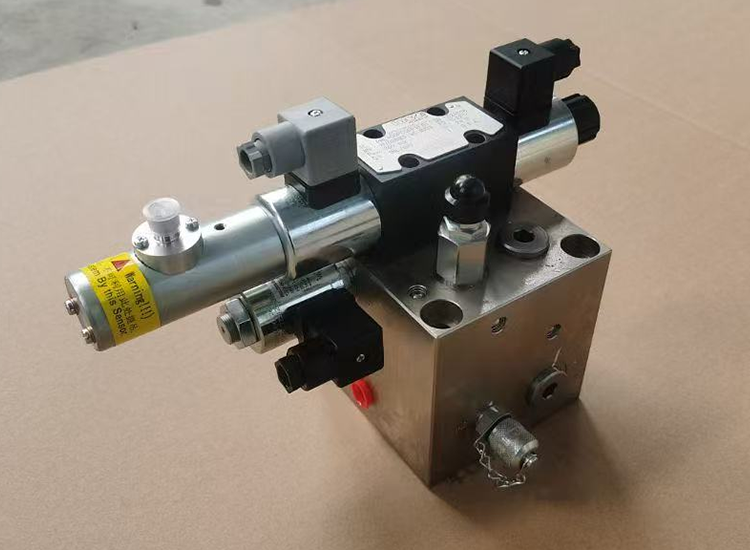

It utilizes a German-imported electro-hydraulic servo valve and a HEIDENHAIN optical scale to form a closed-loop control system. The machine body is designed with a fully welded structure, and the rear stopper mechanism is equipped with imported guide rails and linear bearings. The CNC system supports models from DELEM of the Netherlands and ESA of Italy, offering features such as automatic selection, program calculation, and robotic bending capabilities. The energy consumption while idling is reduced by more than 75%, and the work speed is increased by 15% to 25%. The repeat positioning accuracy of the slide block reaches ±0.01mm.The hydraulic deflection compensation is automatically adjusted by the CNC system.

Applications

The CNC system used in this machine is from DELEM of the Netherlands, ESA of Italy, and CybTouch of Switzerland. Two C-shaped plates are installed on both sides of the machine body. A high-precision optical scale is mounted on the C-shaped plate, which helps to prevent any deformation of the machine body during the bending process from affecting the bending accuracy.

Competitive Advantage

1. Generally, an electric mechanical convex automatic compensation system is used to address the impact of the deformation of the slide block during the bending process on the quality of the workpiece. The amount of compensation is adjusted automatically by the CNC system for convenience and precision.

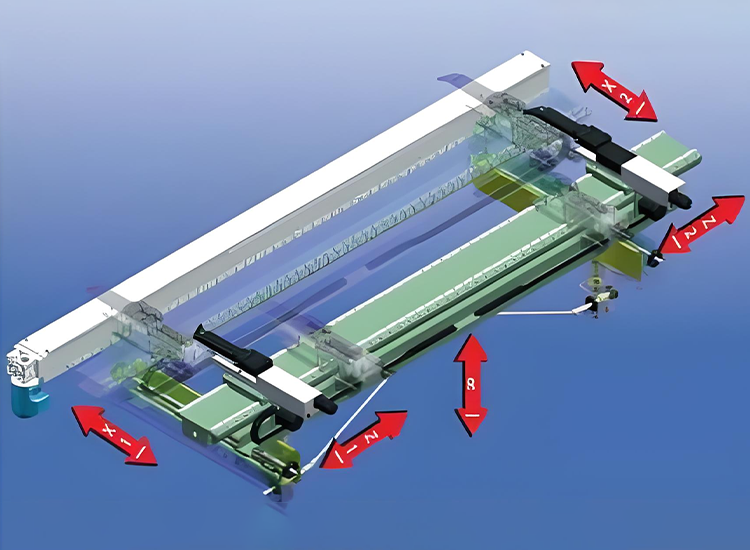

2. A fully functional rear stop mechanism is employed, allowing for the control of multiple rear stop shafts. The functional components within the rear stop, such as guide rails, linear shafts, and bearings, are all made from imported components to ensure the precision of the rear stop.

3. The machine body is constructed using a whole-body welding structure, which facilitates transportation, ease of processing, and ensures the overall precision of the machine.

4. Important components such as the machine body and slide block are analyzed using ANSYS finite element analysis software to ensure the reliability of the machine.

5. The hydraulic system employs a German-made integrated control system, which reduces the need for piping installation, enhances the stability of the machine's operation, and results in a sleek and simple appearance.

Uncoil Leveling Machine

Uncoil Leveling Machine Shearing Machine

Shearing Machine Laser Cutting Machine

Laser Cutting Machine Press Brake Machine

Press Brake Machine Rolling Machine

Rolling Machine Hydraulic press machine

Hydraulic press machine Welding Machine

Welding Machine Robot Arm

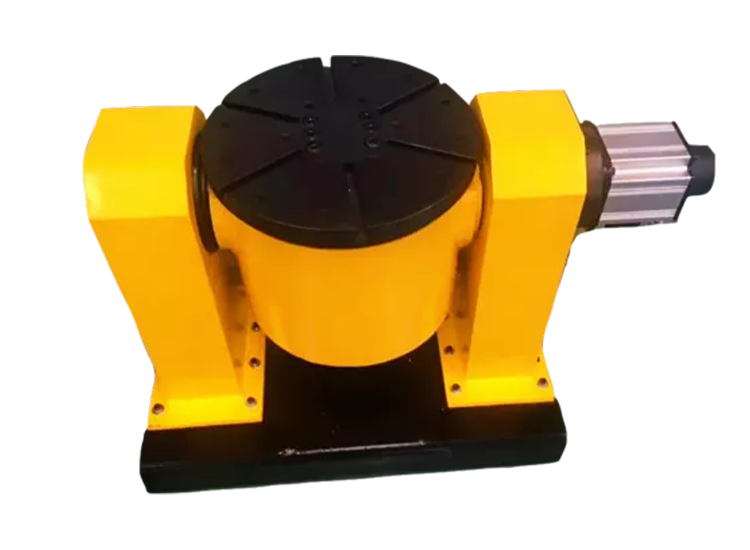

Robot Arm