- Overview

- Recommended Products

| Place of Origin: | CHINA |

| Brand Name: | WEILI |

| Certification: | ISO9001 |

| Minimum Order Quantity: | 1 |

| Price: | Depending on the model number |

| Packaging Details: | Wooden box, waterproof |

| Delivery Time: | 20 days |

| Payment Terms: | 30% deposit,pay the 70% balance before delivery |

| Supply Ability: | Advanced manufacturing capabilities for large-scale orders |

Description

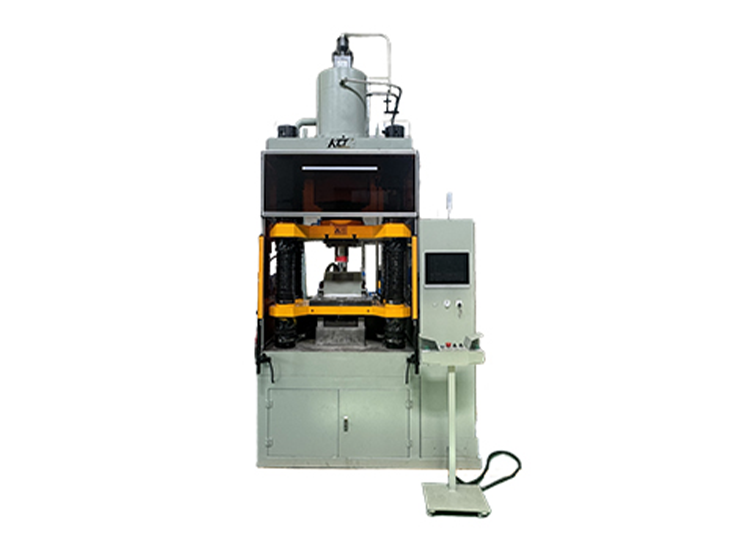

The head sealing hydraulic press (stretching head sealing pressure press) is a device used for the one-time cold or hot pressing forming of head sealing parts. It is also known as a head sealing hydraulic press, head stretching machine, head stamping press, and so on. This machine is a stretching head sealing hydraulic press that can produce large-diameter head sealing parts. The choice of machine model depends on the size and thickness of the head sealing part. The available models include 315-ton, 500-ton, 630-ton, 800-ton, 1000-ton, 1500-ton, 2000-ton, and 2800-ton head sealing hydraulic presses, as well as 3000-ton hydraulic presses.

The head sealing hydraulic press (stretcher head sealing pressure press) is primarily used for the cold and hot forming pressing of various types of pressure vessel head sealing parts. It can also be used for processes such as pressing, bending, and flattening of various thicknesses of steel plates.

Competitive Advantage

1. Efficient production: The sealing hydraulic machine is driven by a hydraulic system, with high working efficiency and production speed. Compared with traditional machining, it can greatly improve the production efficiency and save time and labor costs.

2. Precision molding: The sealing hydraulic machine (stretch sealing pressure machine) applys a uniform, adjustable pressure through the hydraulic cylinder, making the molding process more stable and accurate.This guaranteed the head shape, the size and the level up degree consistency, enhanced the product quality and the reliability.

3. Flexibility and variety: The molds of the sealing hydraulic machine can be replaced according to demand, adapting to the sealing of different shapes and sizes. This makes it more adaptable and flexible, and reduces mold costs while meeting demand.

4. Easy operation: The sealed hydraulic machine uses a hydraulic control system, and the operation is relatively simple, requiring only basic setup and adjustment. Moreover, it also has some automation functions, such as pressure control, position control, etc., further simplifying the operation steps and reducing the difficulty of personnel operating.

5. Energy saving and environmental protection: The sealing hydraulic machine (stretch sealing pressure machine) can use energy efficiently during the work process and reduce energy waste. Compared with traditional machining equipment, it consumes less energy, has a smaller impact on the environment, and meets the requirements of sustainable development.

The sealing hydraulic machine has become an important equipment in the sealing manufacturing industry with its characteristics of efficiency, precision and flexibility. It not only improves production efficiency and product quality, but also saves costs for enterprises and meets the diverse needs of the market.

Uncoil Leveling Machine

Uncoil Leveling Machine Shearing Machine

Shearing Machine Laser Cutting Machine

Laser Cutting Machine Press Brake Machine

Press Brake Machine Rolling Machine

Rolling Machine Hydraulic press machine

Hydraulic press machine Welding Machine

Welding Machine Robot Arm

Robot Arm