- Overview

- Recommended Products

| Place of Origin: | CHINA |

| Brand Name: | WEILI |

| Certification: | ISO9001 |

| Minimum Order Quantity: | 1 |

| Price: | Depending on the model number |

| Packaging Details: | Wooden box, waterproof |

| Delivery Time: | 20 days |

| Payment Terms: | 30% deposit,pay the 70% balance before delivery |

| Supply Ability: | Advanced manufacturing capabilities for large-scale orders |

Description

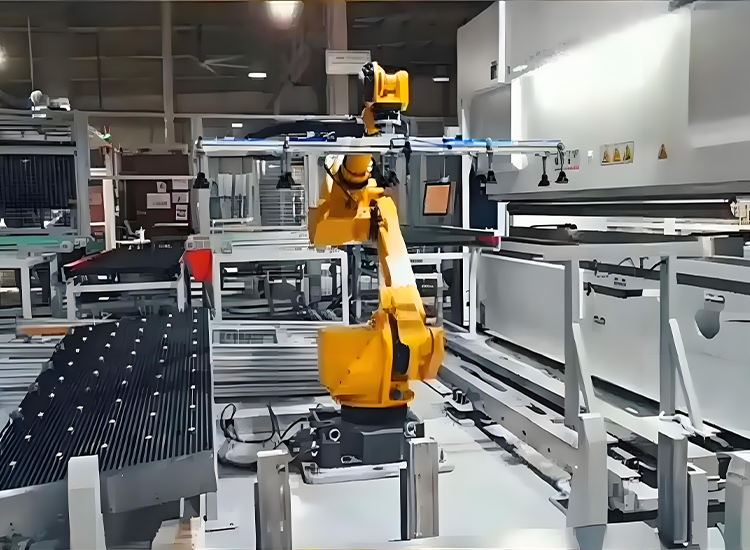

Overview of the Seventh Axis ·

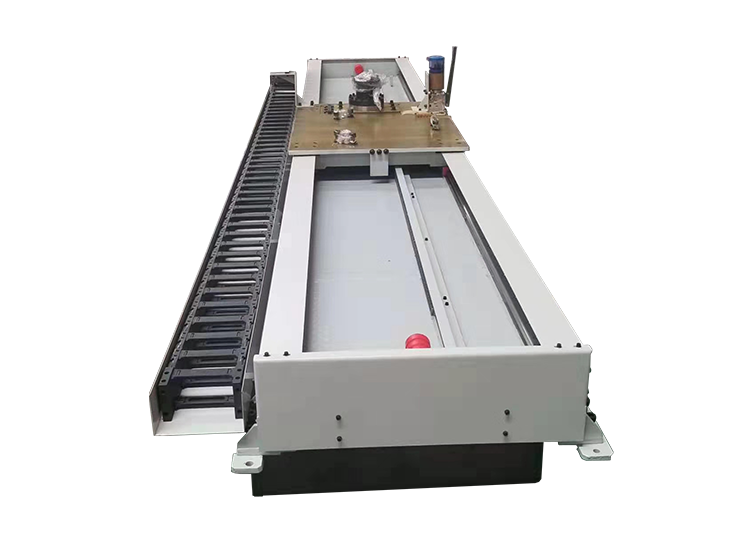

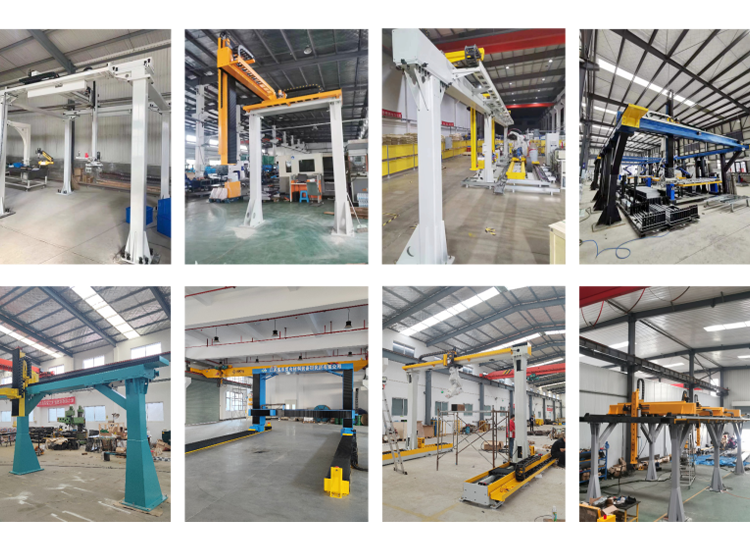

The seventh axis is categorized into three types based on its installation form: open seventh axis, closed seventh axis, and semi-closed seventh axis. ·

The seventh axis for robots works in conjunction with industrial robots to provide horizontal movement. The industrial robot handles the entire production process, including loading, clamping, and unloading, thereby significantly enhancing the quality and aesthetic appeal of the workpieces. ·

It addresses the issue of instability in the quality of products that were previously handled manually. The seventh axis for robots employs a fully servo-driven power system, which ensures high speed, precision, and excellent dust and dirt resistance. ·

It meets the actual needs of automated production lines in factories, including tasks such as loading and unloading workpieces on machine tools, welding, assembly, spraying, inspection, casting, forging, heat treatment, metal cutting processing, and material handling and palletizing.

Specifications

| Model Specification | Body Width (MM) | Load Range (T) | Repeat Positioning Accuracy (MM) | Stroke (M) | Maximum Speed (MM/S) | Lubrication System | Number of Sensor Points (Zero, Positive, Negative) |

| JY100-T500 | 500 | 0.1-0.5 | ±0.05 | 2-100 | 1500 | Solid Automatic | 3 |

| JY100-T1500 | 700 | 0.5-1.5 | ±0.05 | 2-100 | 1000 | Solid Automatic | 3 |

| JY100-T3000 | 800 | 1.5-3.0 | ±0.05 | 2-100 | 1000 | Solid Automatic | 3 |

Competitive Advantage

| Drive Method | Drive Method | Servo Method |

| Load Capacity | Maximum Load Capacity | 0.5-6T (Non-standard) |

| Operation & Application | Operation Type | Construction Machinery |

| Precision | Repeat Positioning Accuracy | ±0.05mm |

| Speed | Moving Speed | 0-60m/min |

| Protection Performance | Protection Level | IP40 |

| Station Configuration | Total Number of Stations | Customized (Non-standard) |

| Dustproof Measure | Dustproof Mode | Semi-enclosed / Fully-enclosed / Bellows Cover |

| Stroke | Effective Stroke | Free Splicing |

| Maintenance | Maintenance Method | Fully Automatic Oil Injection |

① Customized service: tailor-made design, on-site installation, and adjustment.

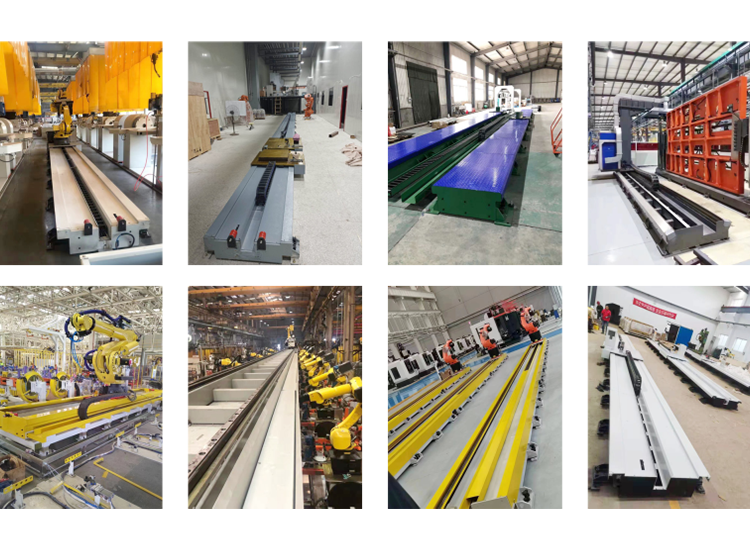

② Extremely long stroke: can be freely connected and expanded up to a maximum of 100 meters in length.

③ Military-grade craftsmanship: undergoes two stages of tempering treatment and has been proven to last up to 100,000 cycles.

④ Smart lubrication: fully automatic oiling system, no need for manual maintenance.

⑤ Multiple protections: IP40 protection level; dust-proof design with accordion cover.

⑥ Rapid response: 1.5m/s speed; precise start and stop with an accuracy of 0.1 seconds.

Uncoil Leveling Machine

Uncoil Leveling Machine Shearing Machine

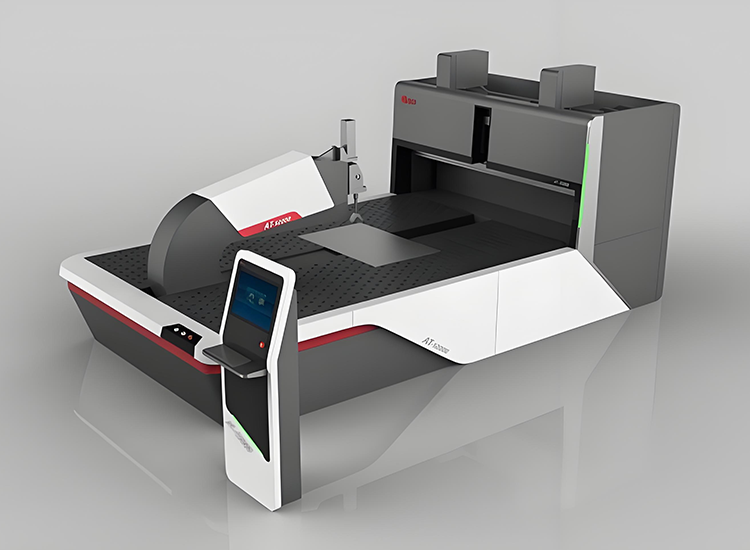

Shearing Machine Laser Cutting Machine

Laser Cutting Machine Press Brake Machine

Press Brake Machine Rolling Machine

Rolling Machine Hydraulic press machine

Hydraulic press machine Welding Machine

Welding Machine Robot Arm

Robot Arm