- Overview

- Recommended Products

| Place of Origin: | CHINA |

| Brand Name: | WEILI |

| Certification: | ISO9001 |

| Minimum Order Quantity: | 1 |

| Price: | Depending on the model number |

| Packaging Details: | Wooden box, waterproof |

| Delivery Time: | 20 days |

| Payment Terms: | 30% deposit,pay the 70% balance before delivery |

| Supply Ability: | Advanced manufacturing capabilities for large-scale orders |

Description

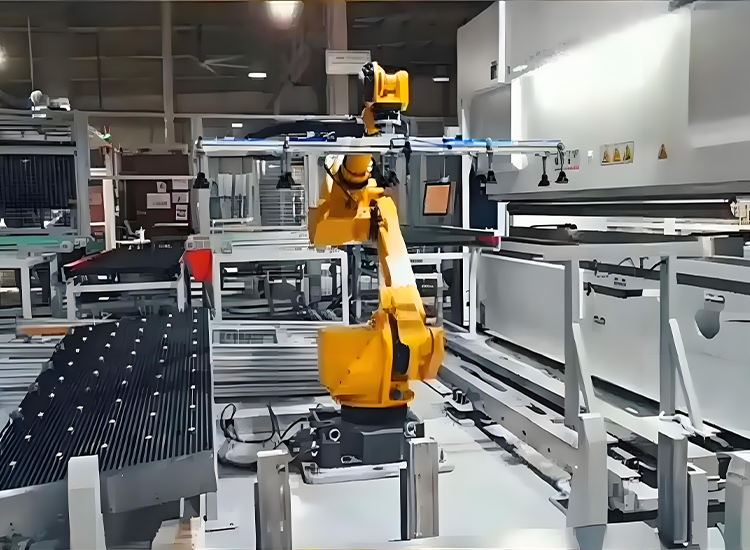

The bending machine hand is an automated device used for bending metal sheets into various shapes. It enables efficient and precise bending operations. The working principle of this machine hand mainly involves a series of precise mechanical movements and sensor control to position the metal sheet in the mold and apply pressure to bend it into the desired shape.

The bending machine hand boasts high precision, efficiency, and adaptability. It can process different shapes of metal sheets by simply changing the mold. It is widely used in industries such as automotive, aerospace, electronics, and construction. By employing advanced mechanical design and technology, the bending robot can achieve precise control and processing of metal sheets, thereby improving production efficiency and product quality.

Competitive Advantage

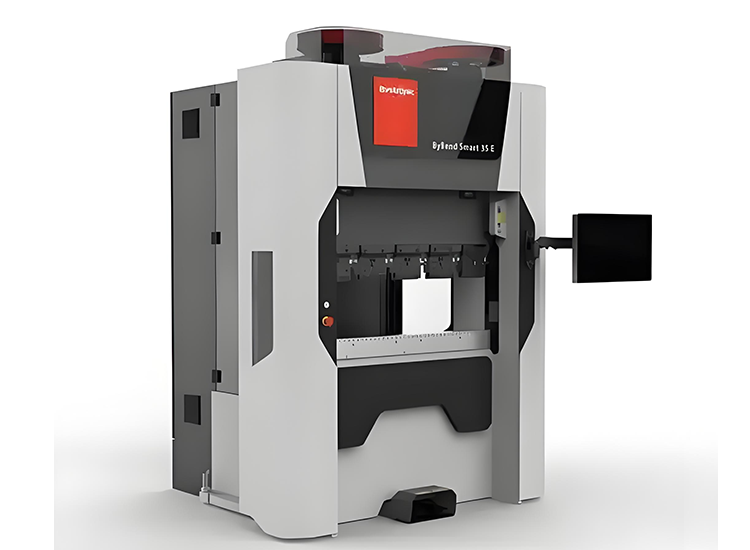

As the core execution component, the CNC plate bending flexible processing unit is a highly automated combination of equipment, featuring high efficiency, high quality, and high flexibility. In the bending flexible processing unit, selecting the appropriate combination of components can provide better support for processing efficiency and flexibility. The bending accuracy depends on the precision of the bending machine itself, the positioning precision of the mechanical hand, and the coordinated control between the mechanical hand and the bending machine. The difficulty of coordinated control lies in matching the speed of the mechanical hand and the bending machine, as well as the operation trajectory of the mechanical hand supporting the workpiece. Poor follow-up performance will significantly affect the forming effect of the bending angle and the flatness of the plate surface, thereby impacting the quality of the finished product.

Uncoil Leveling Machine

Uncoil Leveling Machine Shearing Machine

Shearing Machine Laser Cutting Machine

Laser Cutting Machine Press Brake Machine

Press Brake Machine Rolling Machine

Rolling Machine Hydraulic press machine

Hydraulic press machine Welding Machine

Welding Machine Robot Arm

Robot Arm