- Overview

- Recommended Products

| Place of Origin: | CHINA |

| Brand Name: | WEILI |

| Model Number: | F15GS3015G, F20GS3015G |

| Certification: | ISO9001 |

| Minimum Order Quantity: | 1 |

| Price: | Depending on the model number |

| Packaging Details: | Wooden box, waterproof |

| Delivery Time: | 20 days |

| Payment Terms: | 30% deposit,pay the 70% balance before delivery |

| Supply Ability: | Advanced manufacturing capabilities for large-scale orders |

Description

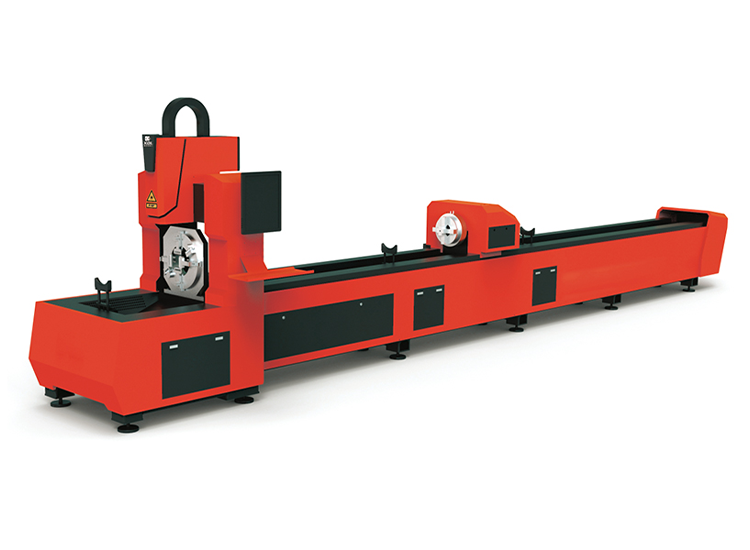

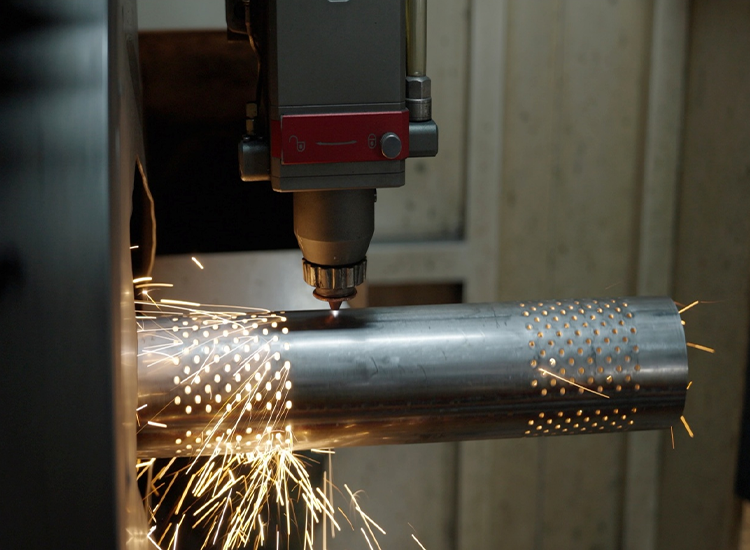

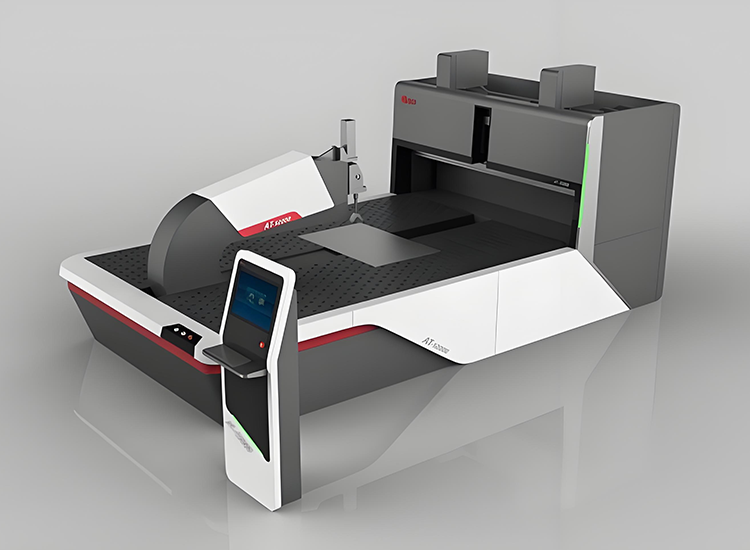

The pipe laser cutting machine is an automated device specifically designed for high-precision cutting of metal pipes (round pipes, square pipes, and irregular-shaped pipes, etc.). It integrates laser technology, CNC system, and mechanical transmission technology.

Applications

WiseCAM LS2000 is a professional operation bus system that is easy to install and simple to debug, with excellent performance.

1. It supports basic processes such as flight cutting, lead wire, seamless micro-connection, and film-covered cutting.

2. It supports advanced functions like two-level punching, capacitance edge detection, electric focus adjustment, automatic layout, and more.

3. It supports advanced processes such as cooling points, QR codes, and cutting lines.

4. It supports precise cutting processes like starting and stopping cutting.

5. It supports early air release and gas flushing.

6. It supports a dual-drive error detection function.

7. It supports process path statistics for easier billing.

Specifications

| Equipment Model | Specification Item | F15GS3015G | F20GS3015G |

| Laser Head | Laser Wavelength | 1070nm | 1070nm |

| Fiber Core Diameter | 50um | 50um | |

| Photoelectric Efficiency | 42%, Low Energy Consumption | 42%, Low Energy Consumption | |

| Laser Pulse Repetition Rate | 5KHZ | 5KHZ | |

| Maximum Laser Output Power | 1500W | 2000W | |

| Maximum Input Power | 4Kw | 5KW | |

| Power Supply | 3PH/AC380V±10%/50HZ | 3PH/AC380V±10%/50HZ | |

| Water Pressure | ≤5bar | ≤5bar | |

| Cutting Head |

Focus Lens | F125 | F125 |

| Collimating Lens | F100 | F100 | |

| Protection Lens | ¢28*4 | ¢28*4 | |

| Cutting Capacity | Max Carbon Steel | 10mm | 16mm |

| Max Stainless Steel | 6mm | 8mm | |

| Bed Parameters | Effective Cutting Range | 3m*1.5m | 3m*1.5m |

| Cutting Head Lifting Stroke | ≤120mm | ≤120mm | |

| X, Y Axis Repeat Positioning Accuracy | ±0.02mm | ±0.02mm | |

| Max X/Y Axis Linkage Speed | 60m/min | 60m/min | |

| Worktable Height from Ground | 650mm | 650mm | |

| Main Machine Dimensions (L×W×H) | 4.6mx2.4mx2m | 4.6mx2.4mx2m | |

| Environmental Requirements | Working Environment Temperature | 0~40 °C | 0~40 °C |

| Power Demand | 3P1N380V(±10%)/50Hz | 3P1N380V(±10%)/50Hz | |

| Total Machine Power (excluding Air Compressor) | 15KW | 17KW |

| Main Components | Fiber Laser | Tianjin Keeplerin or USA GW (Optional) |

| Intelligent Cutting Head | Switzerland RAYTOOLS | |

| Intelligent Water Chiller | Wuhan Hanli | |

| Operating Control System | Operating System | WiseCAM LS2000 |

| Offline Programming & Nesting Software | WiseCAM Flat Nesting Software | |

| Follow-up Tracking System | WiseCAM | |

| Servo Motor | WiseCAM Servo Bus | |

| Precision Transmission | Linear Guideway | Taiwan HIWIN |

| Precision Slide Main Component | Japan THK or NSK | |

| Precision Rack | Taiwan YYC | |

| Precision Gear | Taiwan YYC | |

| Precision Planetary Reducer | Taiwan Faston | |

| Electrical Components | Circuit Breaker | France SCHNEDER |

| Relay | France SCHNEDER | |

| DC Power Supply | France SCHNEDER | |

| Rack Structure | Main Rack | Steel Plate & Profile Hybrid Welding Structure, Stress Relief Treatment; CNC Gantry Integrated Machining |

| Beam Material | Lightweight High-Rigidity Profile Welding | |

| Worktable Exchange Mode | Fixed Table, Non-Exchangeable | |

| Smoke Exhaust Mode | High-Airflow Down-Draft Type | |

| Lubrication Mode | Timed Quantitative Automatic Oiling, Felt Gear Continuous Lubrication | |

| Pneumatic Components | Solenoid Valve | Taiwan AIRTAC |

Competitive Advantage

1. Advanced technology in medium-power fiber lasers;

2. High integration and small size, occupying minimal space;

3. Comes with remote technical support and fault diagnosis capabilities;

4. Low energy consumption, with an optical conversion rate of over 40%;

5. Long lifespan, with a theoretical lifetime of 100,000 hours;

6. Suitable for cutting high-refractive-index metals like aluminum and copper;

7. No external optical path, resulting in low maintenance costs.

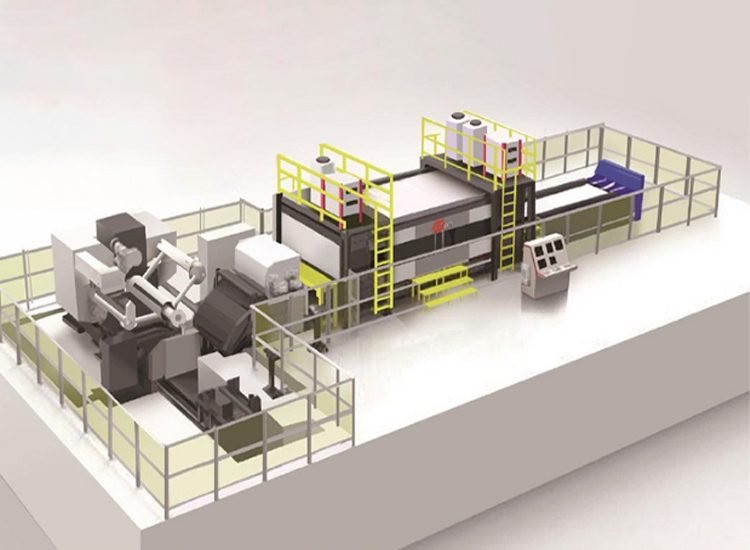

Uncoil Leveling Machine

Uncoil Leveling Machine Shearing Machine

Shearing Machine Laser Cutting Machine

Laser Cutting Machine Press Brake Machine

Press Brake Machine Rolling Machine

Rolling Machine Hydraulic press machine

Hydraulic press machine Welding Machine

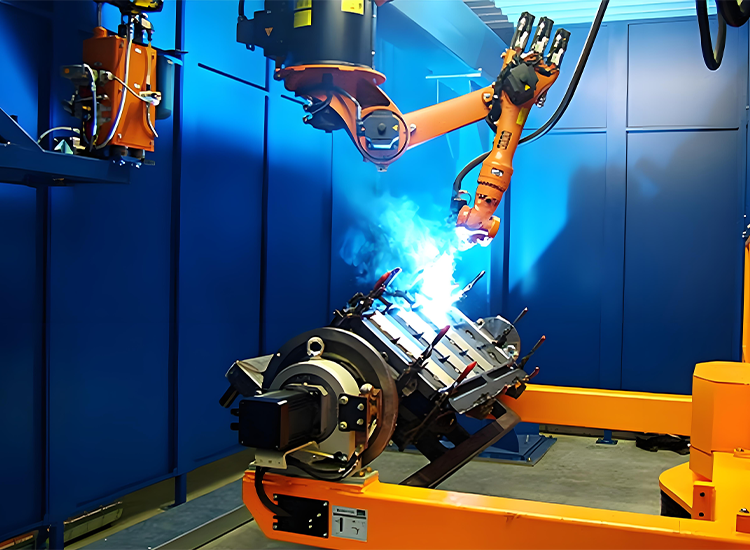

Welding Machine Robot Arm

Robot Arm