- Overview

- Recommended Products

| Place of Origin: | CHINA |

| Brand Name: | WEILI |

| Certification: | ISO9001 |

| Minimum Order Quantity: | 1 |

| Price: | Depending on the model number |

| Packaging Details: | Wooden box, waterproof |

| Delivery Time: | 20 days |

| Payment Terms: | 30% deposit,pay the 70% balance before delivery |

| Supply Ability: | Advanced manufacturing capabilities for large-scale orders |

Description

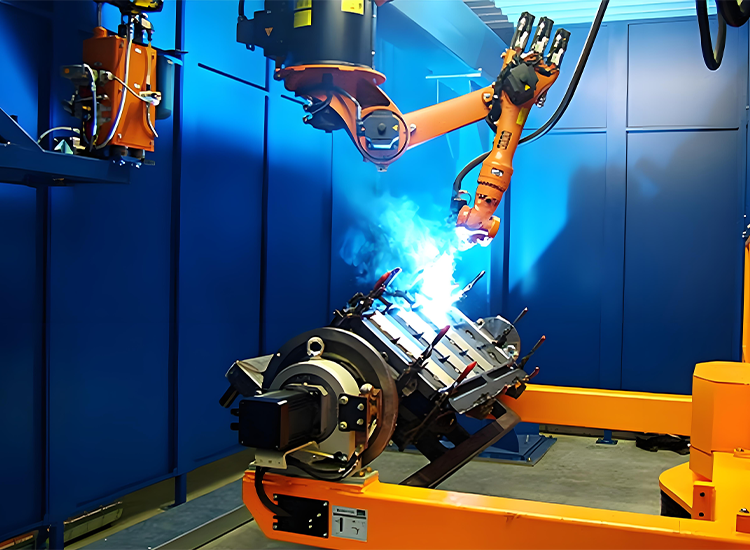

The WeiLi welding robot workstation uses a welding robot arm to weld refrigeration pressure vessels. Based on the different workpieces and weld joints, the robot selects appropriate welding parameters. It also utilizes the built-in weld seam tracking function of the equipment, which has significantly improved the appearance of the weld seam.

When welding thicker sheets, the initial position of the welding point is precisely determined in advance. The arc point distance is reserved from the beginning of product design, and an arc sensor is used for tracking.

This approach effectively avoids the problem of difficulty or inaccuracy in finding the initial welding point due to factors such as oil stains or primer on the surface of the workpiece, which can affect the use of contact sensors.

Competitive Advantage

1.The versatility is high, and the welding of different work parts can be carried out depending on the nature of the work, It can be divided into a variety of corresponding types, and by adjusting the welding parameters, it is possible to welding plates of different thicknesses. Faced with thicker plates, contact sensors and arc sensors are usually used, and different sensors can be used to cooperate with the operation and adapt to the welding of different workpieces.

2.The automation level is high, and there is flexibility to add workplaces. The robot welding workstation mainly consists of several parts, such as the welding robot and its control system, the welding shift machine and the cleaning gun. The robot unit can cooperate with the welding operation with other auxiliary equipment. In order to ensure welding quality, automatic gun cleaning procedures need to be added regularly in the middle, the unit module is simple, and it is free to add robot units or human welding positions, and if parts fail, the machine can be suspended separately and maintained.

4.Due to its high strength, it can guarantee that the welded seam will have a beautiful appearance after forming. Since it is designed for welding refrigeration pressure vessels, it allows for the selection of appropriate welding parameters based on the different workpieces and weld joint. Additionally, it features an automatic weld seam tracking function, which can automatically identify the weld seam and locate it. This is particularly useful for complex-shaped workpieces, as the welding auxiliary equipment can perform rotational movements to enhance the aesthetic appeal of the weld seam after forming.

4.Large-scale welding production with high welding efficiency is achievable. Since robot welding workstations can work continuously for 24 hours without interruption and are less affected by external human factors, they can maintain stable welding quality in harsh environments, making them suitable for batch welding production.

Uncoil Leveling Machine

Uncoil Leveling Machine Shearing Machine

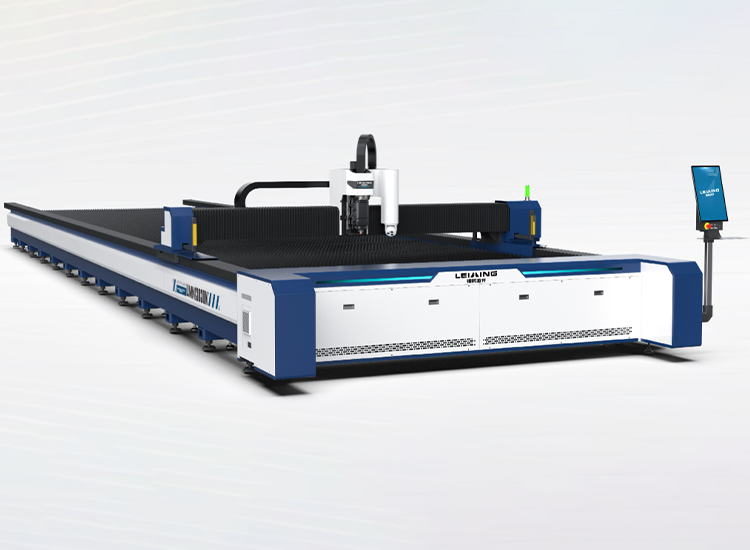

Shearing Machine Laser Cutting Machine

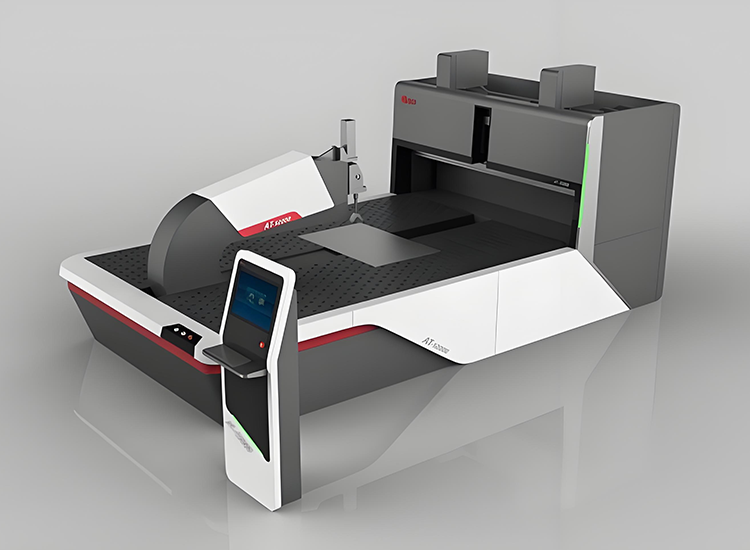

Laser Cutting Machine Press Brake Machine

Press Brake Machine Rolling Machine

Rolling Machine Hydraulic press machine

Hydraulic press machine Welding Machine

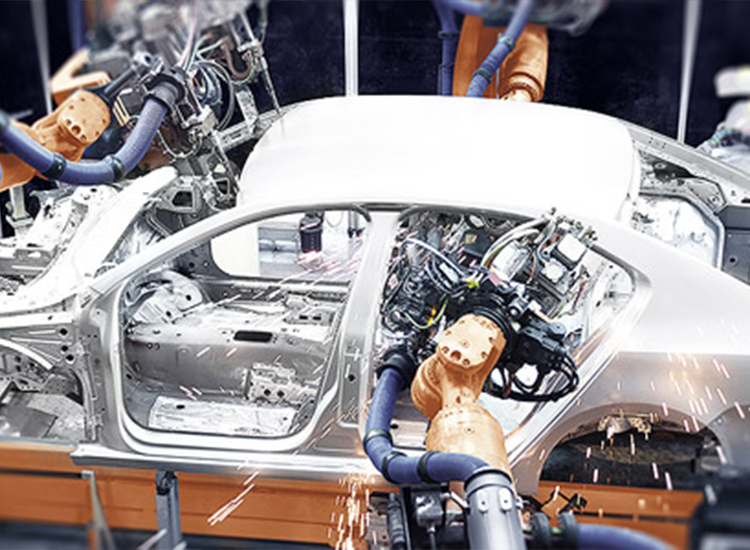

Welding Machine Robot Arm

Robot Arm