- Overview

- Recommended Products

| Place of Origin: | CHINA |

| Brand Name: | WEILI |

| Certification: | ISO9001 |

| Minimum Order Quantity: | 1 |

| Price: | Depending on the model number |

| Packaging Details: | Wooden box, waterproof |

| Delivery Time: | 20 days |

| Payment Terms: | 30% deposit,pay the 70% balance before delivery |

| Supply Ability: | Advanced manufacturing capabilities for large-scale orders |

Description

An electric welding machine is actually a transformer with a decreasing output characteristic. It converts 220V and 380V AC power into low-voltage DC power. Electric welding machines can generally be categorized into two types based on the type of output power source: AC and DC. A DC electric welding machine can be described as a high-power rectifier. It has positive and negative terminals. When AC power is input, it is first stepped up by a transformer and then rectified by a rectifier. The resulting power has a decreasing output characteristic. When the output terminals are connected or disconnected, there is a significant voltage change. When the two terminals are momentarily short-circuited, an arc is ignited, and the arc is used to melt the welding rod and filler material. After cooling, they are fused together. Welding transformers have their own unique characteristics, with the output voltage dropping sharply after the welding rod is ignited.

Competitive Advantage

1. Reasonably designed for free adjustment. Different discharge frequency settings can be chosen based on the type of metal material to achieve the best repair results.

2. Small heat-affected zone. There is no heat input during the instant deposition process, resulting in no deformation, chamfering, or residual stress. No localized annealing occurs, and no need for additional heat treatment after the repair.

3. Minimal impact on the workpiece. This welding machine effectively mitigates the impact caused by ordinary argon arc welding on the surrounding area of the workpiece. Repairs can be performed even on workpieces with no additional material.

4. High precision of repair. The thickness of the deposited material ranges from several micrometers to several millimeters, which can be easily buffed and polished.

5. High fusion strength. Due to the thorough penetration into the surface material of the workpiece, a strong bonding force is achieved.

6. Advanced ring-shaped precision control.

Uncoil Leveling Machine

Uncoil Leveling Machine Shearing Machine

Shearing Machine Laser Cutting Machine

Laser Cutting Machine Press Brake Machine

Press Brake Machine Rolling Machine

Rolling Machine Hydraulic press machine

Hydraulic press machine Welding Machine

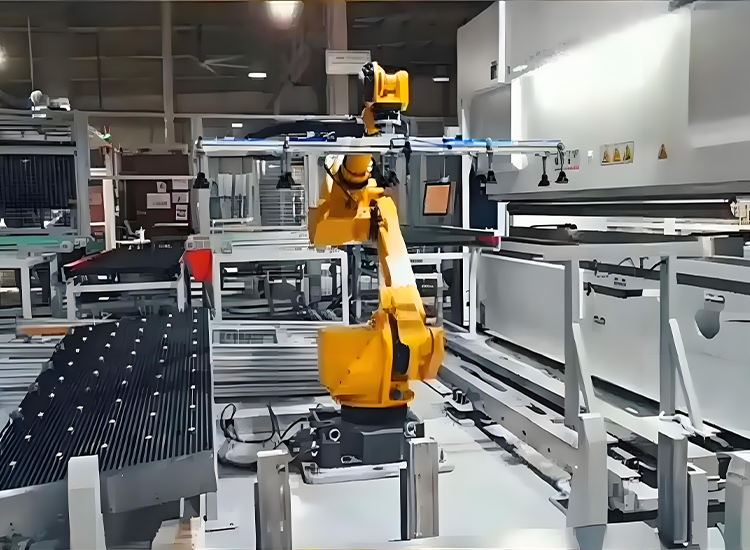

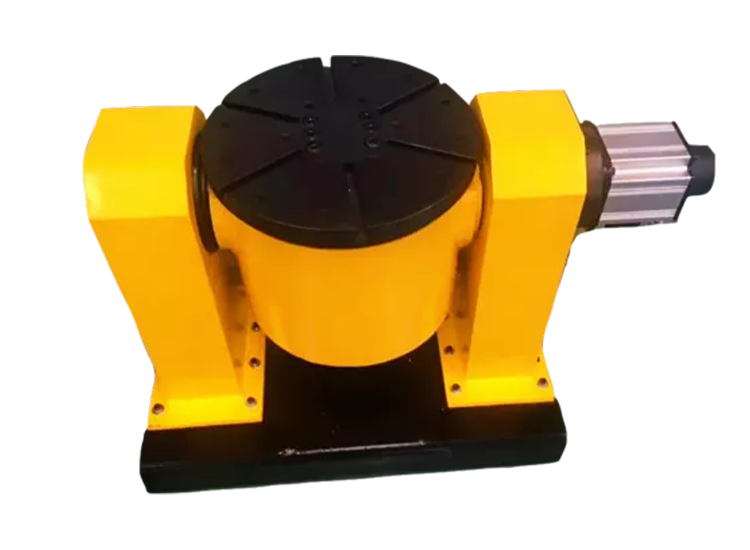

Welding Machine Robot Arm

Robot Arm