- Overview

- Recommended Products

| Place of Origin: | CHINA |

| Brand Name: | WEILI |

| Certification: | ISO9001 |

| Minimum Order Quantity: | 1 |

| Price: | Depending on the model number |

| Packaging Details: | Wooden box, waterproof |

| Delivery Time: | 20 days |

| Payment Terms: | 30% deposit,pay the 70% balance before delivery |

| Supply Ability: | Advanced manufacturing capabilities for large-scale orders |

Description

The Weili MG series movable-type electro-hydraulic CNC bending machine is ideal for beginners. It is easy to operate and suitable for processing thin metal sheets and other general metal bending orders. This machine is incredibly simple to operate; you can learn it in just two hours. It makes it easy to handle various bending angles, even for operators with limited experience. Even without trial processing, the machine can achieve the desired angle.

In terms of pressure application design, this machine uses intermediate pressure, which helps prevent deformation in the middle of the product and ensures accurate processing.

The stability of the equipment is also crucial for various precision issues encountered during actual operation. The Lages movable-type bending machine maintains the highest level of stability in a multi-faceted production environment. With a fully steel-welded frame and a recessed frame design, it maintains high rigidity while ensuring that the frame will not become misaligned or deformed over time, and the precision will not be compromised.

This type of bending machine is suitable for applications such as elevator components, kitchen cabinets, file cabinets, and fire doors, all of which are made from flexible materials. The movable-type electro-hydRAulic CNC bending machine can bend these materials according to the dimensions of the sheet metal, including complex shapes such as large curved arcs, rounded corners, and curves.

Competitive Advantage

1. Generally, an electric mechanical convex automatic compensation system is used to address the impact of the deformation of the slide block during the bending process on the quality of the workpiece. The amount of compensation is adjusted automatically by the CNC system for convenience and precision.

2. A fully functional rear stop mechanism is employed, allowing for the control of multiple rear stop shafts. The functional components within the rear stop, such as guide rails, linear shafts, and bearings, are all made from imported components to ensure the precision of the rear stop.

3. The machine body is constructed using a whole-body welding structure, which facilitates transportation, ease of processing, and ensures the overall precision of the machine.

4. Important components such as the machine body and slide block are analyzed using ANSYS finite element analysis software to ensure the reliability of the machine.

5. The hydraulic system employs a German-made integrated control system, which reduces the need for piping installation, enhances the stability of the machine's operation, and results in a sleek and simple appearance.

Uncoil Leveling Machine

Uncoil Leveling Machine Shearing Machine

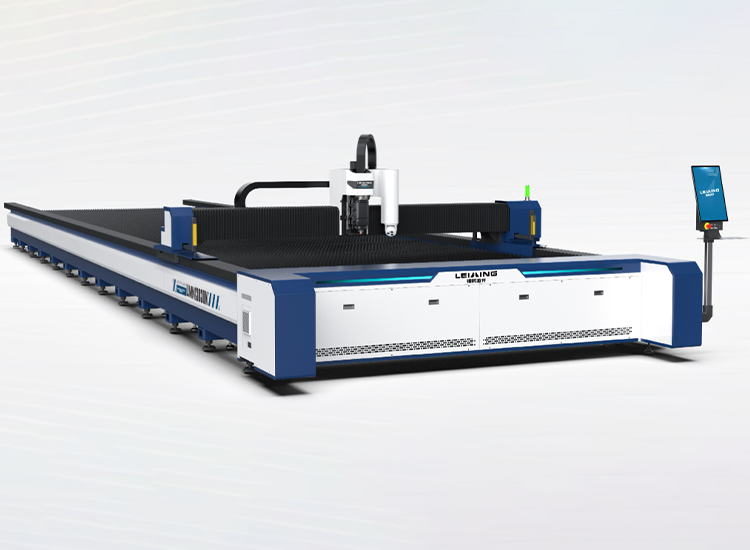

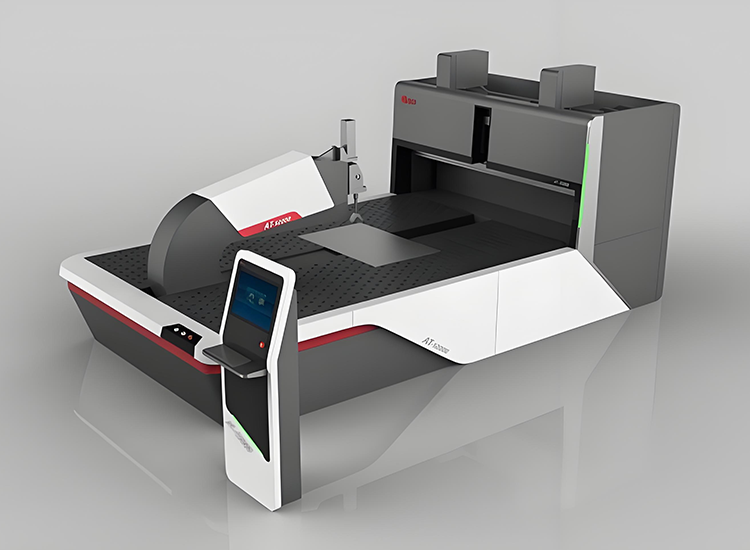

Shearing Machine Laser Cutting Machine

Laser Cutting Machine Press Brake Machine

Press Brake Machine Rolling Machine

Rolling Machine Hydraulic press machine

Hydraulic press machine Welding Machine

Welding Machine Robot Arm

Robot Arm