- Overview

- Recommended Products

| Place of Origin: | CHINA |

| Brand Name: | WEILI |

| Certification: | ISO9001 |

| Minimum Order Quantity: | 1 |

| Price: | Depending on the model number |

| Packaging Details: | Wooden box, waterproof |

| Delivery Time: | 20 days |

| Payment Terms: | 30% deposit,pay the 70% balance before delivery |

| Supply Ability: | Advanced manufacturing capabilities for large-scale orders |

Description

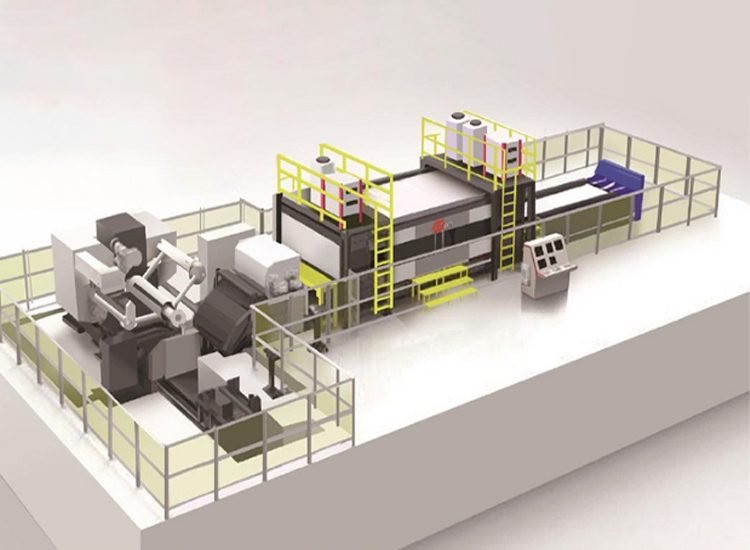

This series of products consists of two parts: the main machine and the rapid tool changer system. The main machine can be designed as a frame structure or a four-column structure. The rapid tool changer system includes various mobile forms and multiple numbers of movable worktables, heavy-duty tool changer carts, a rapid mold clamping mechanism, and a mold recognition system.

This equipment is primarily used for the process of securing (bonding) the left and right door panels, the trunk lid, and the engine hood, as well as for the punching and cutting edge processes. The press machine is usually equipped with a rapid tool-changing system, which includes multiple types of movable worktables, automatic mold clamping mechanisms, and a mold automatic identification system.

Competitive Advantage

This series of products adopts optimized design based on finite element stress analysis. The welding of structural components is performed using a German KUKA welding robot. After welding, heat treatment is conducted according to standards to eliminate welding residual stresses. The parts are then machined using a five-axis center, which ensures good equipment precision, a long lifespan, and protection of the mold.

The servo zero-pressure micro-adjustment function allows for accurate alignment and mold repair.

The system is controlled by a PLC touchscreen interface, and the parameters of the press can be stored and recalled as needed.

Optional interface for integrating the motion control system of the workshop and the automated production line control system for robots.

Rapid mold clamping system.

Movable worktable that can move forward, sideways, in a T-shape, and in a H-shape (with four movable tables).

Light curtain safety protection device.

Mobile safety radar scanner.

Uncoil Leveling Machine

Uncoil Leveling Machine Shearing Machine

Shearing Machine Laser Cutting Machine

Laser Cutting Machine Press Brake Machine

Press Brake Machine Rolling Machine

Rolling Machine Hydraulic press machine

Hydraulic press machine Welding Machine

Welding Machine Robot Arm

Robot Arm