- Overview

- Recommended Products

| Place of Origin: | CHINA |

| Brand Name: | WEILI |

| Certification: | ISO9001 |

| Minimum Order Quantity: | 1 |

| Price: | Depending on the model number |

| Packaging Details: | Wooden box, waterproof |

| Delivery Time: | 20 days |

| Payment Terms: | 30% deposit,pay the 70% balance before delivery |

| Supply Ability: | Advanced manufacturing capabilities for large-scale orders |

Description

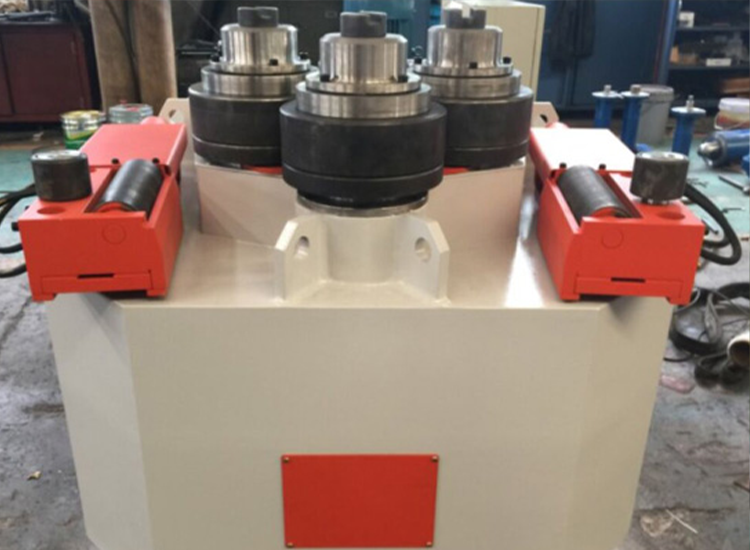

This 16-profile bending machine is a type of arc-lowering three-roller bending machine. The bed frame is made of steel plate components that have undergone internal stress relief treatment. The transmission of the main roller's motion is achieved through an hydraulic system that includes an hydraulic motor, gears, and a chain wheel. The two side rollers move in an arc around the central axis. The motion of both the side rollers and the main roller is transmitted through the hydraulic system, which includes an hydraulic motor, gears. The support rollers are mounted on the side rollers, allowing them to move in an arc along with the side rollers. This setup ensures the precision of the bent profile. Depending on the requirements of the site and the profile, the machine can be installed either vertically or horizontally.

The 16-profile bending machine features full three-roller drive, enabling pre-bending of the profile's end. By adjusting the guide rollers, the machine can correct any distortions that may occur during the non-symmetrical bending process. All actions are controlled by buttons on the electrical control cabinet. Displacement data is displayed with a precision of 0.1 mm. The machine is capable of bending profiles of various shapes based on the profile's cross-sectional shape. The advantages of this type of equipment include high precision and efficiency in bending profiles.

Competitive Advantage

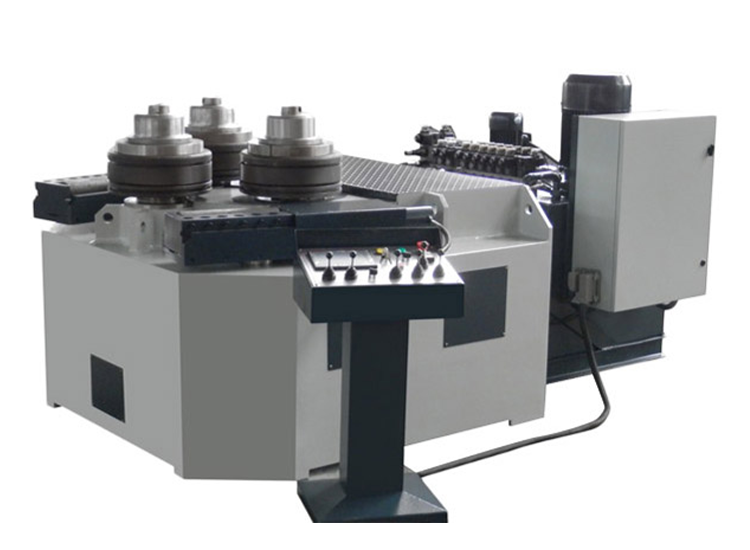

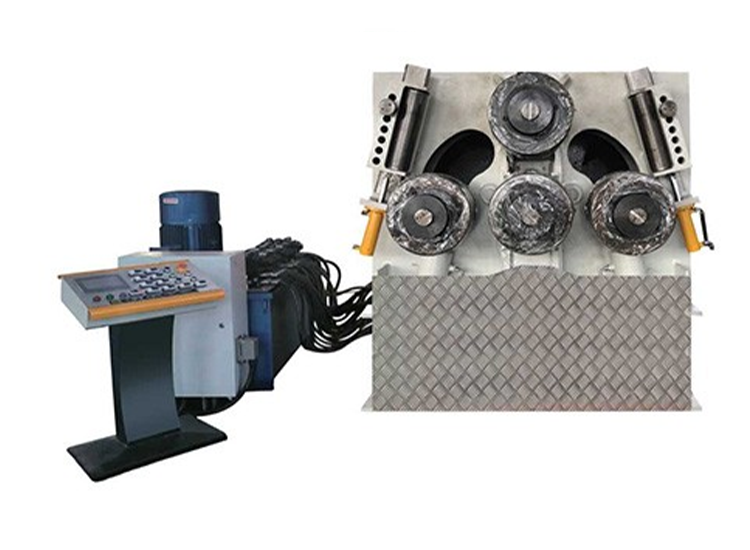

The four-roller profile bending machine is divided into two types: flat bending and vertical bending. It is used for bending flat steel, square steel, round steel, angle steel, I-section steel, H-section steel, square pipe, rectangular pipe, round pipe and other profiles. The four rollers are all driven by active rollers and four independent liquid pressure motors. The rolling speed and efficiency are high. Different molds can be ordered according to the user's requirements.

The four-wheel typecast bending machine is a curved typecast clanging machine, and the two side rollers of the machine are the main drive rollers, and can also be three or four. The four working rollers are main driving rollers, the position of the upper roller is fixed, the two side rollers move around the center of turning circle.

The four-rolled mold bending machine is currently a relatively advanced mold forming equipment at home and abroad, which can complete the pre-bending, rounding and rounding process of the mold at once. The structure is advanced and full of functions, and can be set up or lying down according to the user's use, and is widely used in the production of various garden fixtures in petroleum, chemical industry, steel construction, mechanical manufacturing and other industries.

Uncoil Leveling Machine

Uncoil Leveling Machine Shearing Machine

Shearing Machine Laser Cutting Machine

Laser Cutting Machine Press Brake Machine

Press Brake Machine Rolling Machine

Rolling Machine Hydraulic press machine

Hydraulic press machine Welding Machine

Welding Machine Robot Arm

Robot Arm