- Overview

- Recommended Products

| Place of Origin: | CHINA |

| Brand Name: | WEILI |

| Model Number: | QC12Y-4×2500, QC12Y-4×3200, etc. |

| Certification: | ISO9001 |

| Minimum Order Quantity: | 1 |

| Price: | Depending on the model number |

| Packaging Details: | Wooden box, waterproof |

| Delivery Time: | 20 days |

| Payment Terms: | 30% deposit,pay the 70% balance before delivery |

| Supply Ability: | Advanced manufacturing capabilities for large-scale orders |

Description

Features:

1. Hydraulic transmission and swing-type knife holder; the entire machine frame is welded together for strength and durability; the return stroke of the oil cylinder using an accumulator is smooth and rapid.

2. The machine has a function that allows for no-step adjustment of the travel range; the upper knife has two blades, while the lower knife has four blades. The gap between the blade edges can be adjusted using a handle. The uniformity of the blade gap is easy to fine-tune.

3. A safety guard and electrical interlock ensure safe operation.

4. The machine's clamping plate is equipped with a separate hydraulic clamping device, and each clamping device has a plastic foot at its end.

5. A specialized CNC system, E20, is used for the rear stop material cutting machine. The number of cuts can be displayed digitally.

6. The rolling support device not only reduces frictional resistance but also ensures that the workpiece's surface is not scratched.

7. The entire structure is made of high-strength, fully steel-welded components; this design eliminates internal stresses, resulting in high strength and excellent rigidity.

8. The system uses hydraulic up-motion transmission, providing smooth and reliable operation.

Specifications

| Machine tool model | Maximum plate thickness (mm) | Maximum plate width (mm) |

Shearing angle | Number of strokes | Back stop range (mm) | Main motor power (YW) |

| QC12Y-4×2500 | 4 | 2500 | 1°30' | 18 | 20-600 | 4 |

| QC12Y-4×3200 | 4 | 3200 | 1°30' | 18 | 20-600 | 7.5 |

| QC12Y-4×4000 | 4 | 4000 | 1°30' | 12 | 20-600 | 7.5 |

| QC12Y-4×6000 | 4 | 6000 | 1°30' | 7 | 20-800 | 11 |

| QC12Y-6×2500 | 6 | 2500 | 1°30' | 18 | 20-600 | 7.5 |

| QC12Y-6×3200 | 6 | 3200 | 1°30' | 14 | 20-600 | 7.5 |

| QC12Y-6×4000 | 6 | 4000 | 1°30' | 12 | 20-600 | 7.5 |

| QC12Y-6×6000 | 6 | 6000 | 1°30' | 8 | 20-800 | 11 |

| QC12Y-8×2500 | 8 | 2500 | 1°30' | 14 | 20-600 | 11 |

| QC12Y-8×3200 | 8 | 3200 | 1°30' | 12 | 20-600 | 11 |

| QC12Y-8×4000 | 8 | 4000 | 1°30' | 10 | 20-600 | 11 |

| QC12Y-10×2500 | 10 | 2500 | 1°30' | 10 | 20-600 | 11 |

| QC12Y10×3200 | 10 | 3200 | 1°30' | 10 | 20-600 | 11 |

| QC12Y-10×4000 | 10 | 4000 | 1°30' | 8 | 20-600 | 11 |

| QC12Y-12×2500 | 12 | 2500 | 2° | 10 | 20-600 | 15 |

| QC12Y-12×3200 | 12 | 3200 | 2° | 9 | 20-600 | 15 |

| QC12Y-12×4000 | 12 | 4000 | 2° | 8 | 20-600 | 18.5 |

| QC12Y-16×2500 | 16 | 2500 | 2° | 8 | 20-800 | 18.5 |

| QC12Y-16×3200 | 16 | 3200 | 2° | 7 | 20-600 | 18.5 |

| QC12Y-16×4000 | 16 | 4000 | 2° | 6 | 20-600 | 18.5 |

| QC12Y-20×2500 | 20 | 2500 | 2°30' | 7 | 20-800 | 22 |

| QC12Y-20×3200 | 20 | 3200 | 2°30' | 6 | 20-800 | 22 |

| QC12Y-20×4000 | 20 | 4000 | 2°30' | 5 | 20-800 | 22 |

| QC12Y-25×2000 | 25 | 2000 | 3° | 8 | 20-800 | 37 |

| QC12Y-25×2500 | 25 | 2500 | 3° | 6 | 20-800 | 37 |

| QC12Y-25×3200 | 25 | 2500 | 3° | 6 | 20-800 | 37 |

| QC12Y-25×4000 | 25 | 4000 | 3° | 5 | 20-800 | 37 |

| QC12Y-32×2500 | 32 | 2500 | 3.5° | 5 | 20-1000 | 45 |

| QC12Y-32×3200 | 30 | 3200 | 3.5° | 5 | 20-1000 | 45 |

| QC12Y-40×2500 | 40 | 2500 | 4° | 4 | 20-1000 | 55 |

| QC12Y-40×3200 | 40 | 3200 | 4° | 4 | 20-1000 | 75 |

| QC12Y-50×2500 | 50 | 2500 | 4° | 3 | 20-1000 | 90 |

Uncoil Leveling Machine

Uncoil Leveling Machine Shearing Machine

Shearing Machine Laser Cutting Machine

Laser Cutting Machine Press Brake Machine

Press Brake Machine Rolling Machine

Rolling Machine Hydraulic press machine

Hydraulic press machine Welding Machine

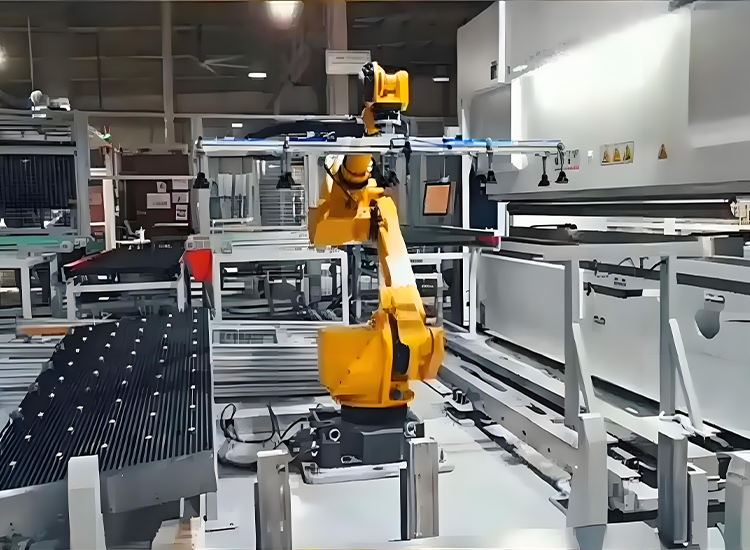

Welding Machine Robot Arm

Robot Arm