- Overview

- Recommended Products

| Place of Origin: | CHINA |

| Brand Name: | WEILI |

| Certification: | ISO9001 |

| Minimum Order Quantity: | 1 |

| Price: | Depending on the model number |

| Packaging Details: | Wooden box, waterproof |

| Delivery Time: | 20 days |

| Payment Terms: | 30% deposit,pay the 70% balance before delivery |

| Supply Ability: | Advanced manufacturing capabilities for large-scale orders |

Description

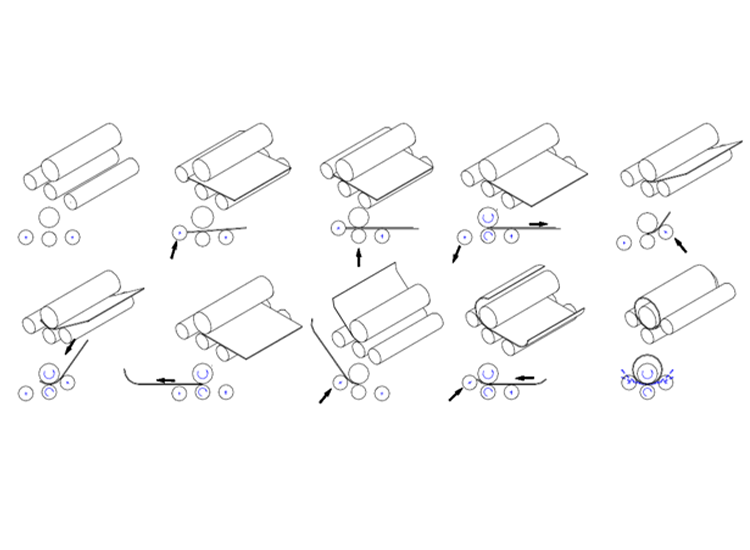

This equipment features a pre-bending function for the end of the sheet material, allowing for the metal sheet to be fed into the machine in one piece, with the pre-bending of the sheet end and the rolling and shaping of the workpiece being completed without the need for a change of direction.

The working roll on this machine serves as the primary drive roll, while the lowering and raising of the lower roll and the rolls on both sides are controlled by hydraulic transmission.

The movement of the rollers is controlled by a computer, which also automatically levels the workpiece and displays the information on the screen. For the flipping of the bearing body, hydraulic transmission is used, and a balance mechanism is installed at the rear end of the upper roll to facilitate the easy removal of the workpiece and the cylindrical body after rolling.

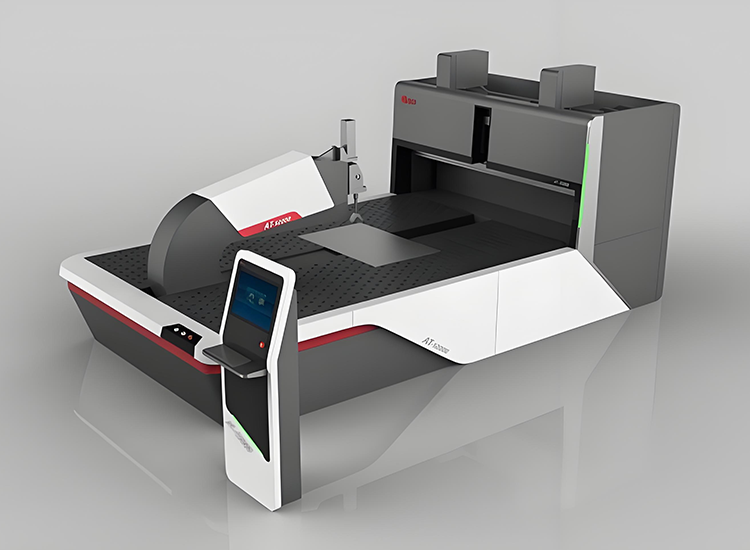

A movable, independent operation platform is also provided, allowing for easy movement and operation of the machine. The machine is equipped with a safety interlock device, and it boasts high technological standards, comprehensive functionality, high precision, and ease of operation.

It is an ideal choice for industries such as energy, transportation, petroleum, chemical processing, boilers, shipbuilding, hydropower, and metal structures, where the rolling of circular, curved, and tapered workpieces is required.

Competitive Advantage

1. High-load linear sliding guide rail mounted on the machine column, used for the horizontal movement of the lower roll and side rolls

2. Electronic parallel control system

3. Synchronization and balance control of the working roll is fully controlled electronically

4. Variable tilt control for the side roll and lower roll, in both positive and negative directions

5. Conical device capable of forming conical cylindrical bodies

6. Rollers driven by a Du-type hydraulic motor - Anti-friction material in the sliding area - Instantaneous braking of the working roll for high safety

7. Reverse hydraulic drive

8. Movable control panel station with low-pressure control

9. Movable control buttons for easy operation

Uncoil Leveling Machine

Uncoil Leveling Machine Shearing Machine

Shearing Machine Laser Cutting Machine

Laser Cutting Machine Press Brake Machine

Press Brake Machine Rolling Machine

Rolling Machine Hydraulic press machine

Hydraulic press machine Welding Machine

Welding Machine Robot Arm

Robot Arm