- Overview

- Recommended Products

| Place of Origin: | CHINA |

| Brand Name: | WEILI |

| Certification: | ISO9001 |

| Minimum Order Quantity: | 1 |

| Price: | Depending on the model number |

| Packaging Details: | Wooden box, waterproof |

| Delivery Time: | 20 days |

| Payment Terms: | 30% deposit,pay the 70% balance before delivery |

| Supply Ability: | Advanced manufacturing capabilities for large-scale orders |

Description

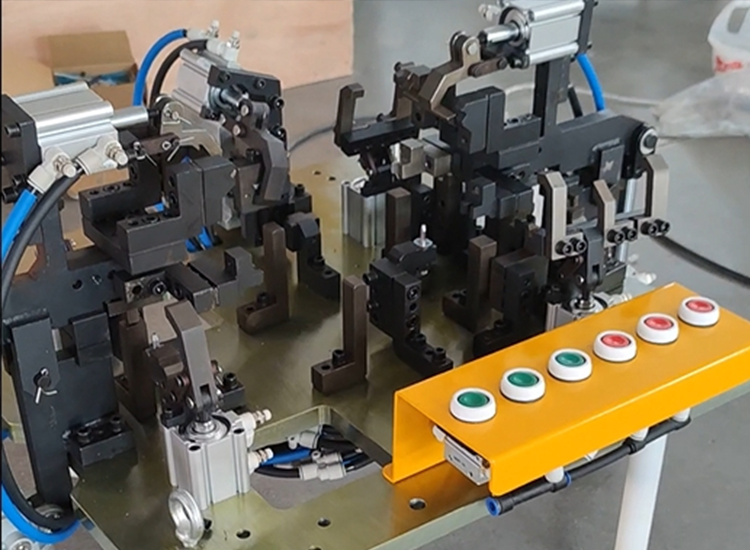

The welding fixture consists of three parts: a positioning device, a clamping mechanism, and a clamping body.

After using the welding fixture, a lot of auxiliary work (such as drawing lines, aligning, measuring, spot-welding, and flipping the workpiece) can be eliminated.

The time required for auxiliary work may vary depending on the specific welding piece.

Proper use of the welding fixture can generally reduce auxiliary time by 50-90% and increase production efficiency.

Competitive Advantage

Accurate and Reliable:

01 Accurate and reliable positioning and clamping can reduce or even eliminate the need for material removal and marking operations. This minimizes dimensional variations in the finished product, thereby improving the precision and interchangeability of components.

Preventing Welding Deformation

02 When a welded piece is welded in a free state, it usually undergoes deformation after welding. By using a welding fixture, the welded piece can be precisely positioned and securely clamped, thereby limiting its deformation during the welding process.

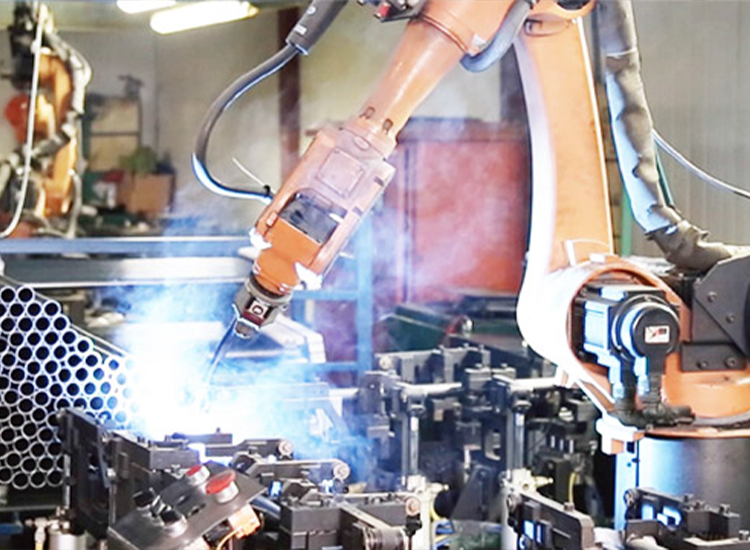

The welding speed has been improved

03The workpiece is placed in an ideal position for welding, resulting in good weld formation and significantly reduced manufacturing defects. This leads to an increase in welding speed.

Scalability

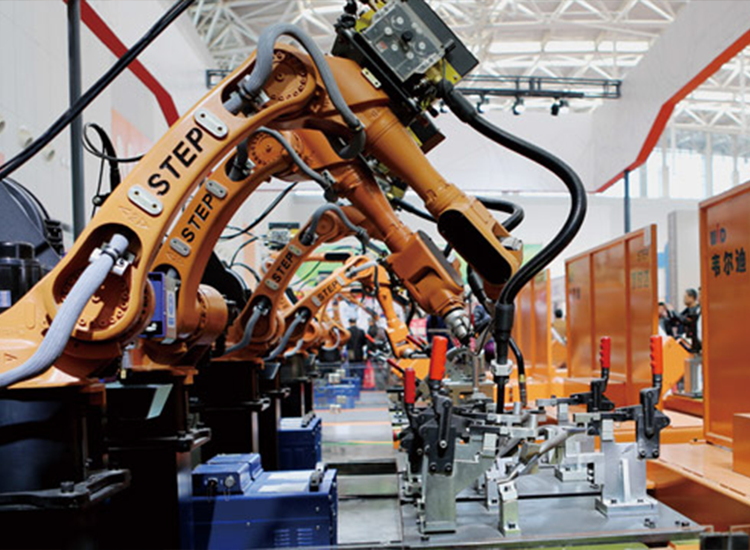

The use of mechanical devices has replaced the labor-intensive tasks such as positioning, clamping, and flipping of workpieces during the manual assembly process, thereby improving the working conditions for workers.

Expand the scope of use

This can expand the application range of the processing method and promote the comprehensive development of mechanization and automation in the production of welded structures.

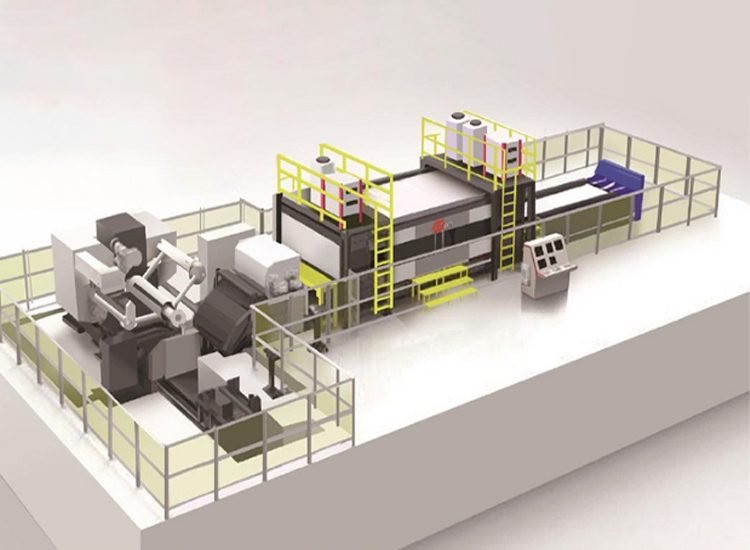

Uncoil Leveling Machine

Uncoil Leveling Machine Shearing Machine

Shearing Machine Laser Cutting Machine

Laser Cutting Machine Press Brake Machine

Press Brake Machine Rolling Machine

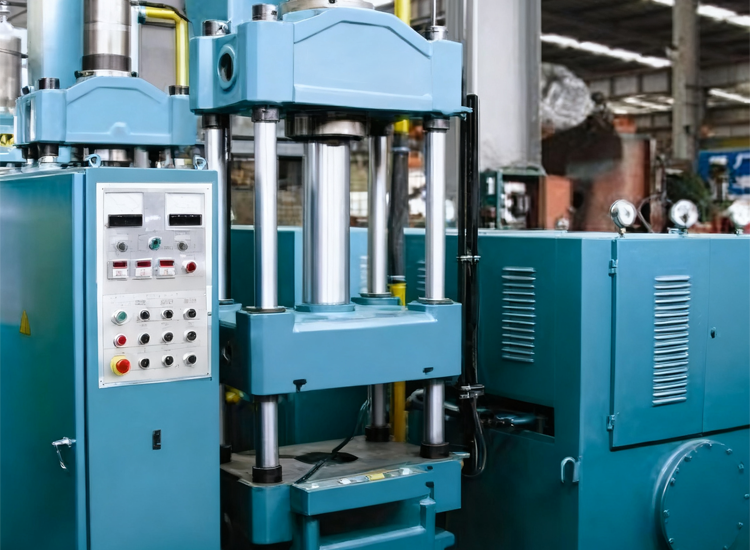

Rolling Machine Hydraulic press machine

Hydraulic press machine Welding Machine

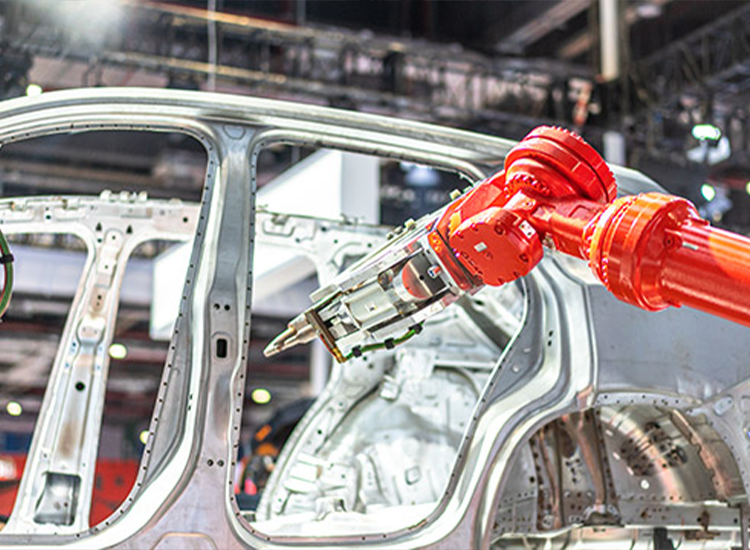

Welding Machine Robot Arm

Robot Arm