- Conspectus

- Producta Commendata

| Locus originis: | China |

| Nomen marcae: | WEILI |

| Numerus modeli: | QC12Y-4×2500, QC12Y-4×3200, etc. |

| Certificatio: | ISO9001 |

| Quantitas minima ordinis: | 1 |

| Pretium: | Dependente a numero moduli |

| Particularia impaquetandi: | Cista lignea, impermeabilis |

| Tempus solutionis: | 20 Diesibus |

| Conditiones solutionis: | praestatio 30%, solvere reliquum 70% ante distributionem |

| Vis Supplicandi: | Capacitates manufacturales adordines magnae magnitudinis |

Descriptio

Peculiaritates:

1. Transmissio hydraulica et armarium cultris oscillans; tota machina fabricata ex structura soldata pro robore et duretate; cursus reditus cylindri olei per accumulatorem est levis et rapidus.

2. Machina habet functionem quae permittit adjustmentem sine gradu campi cursus; culter superior duas habet oras, dum inferior quattuor oras habet. Intervallum inter oras cultris regi potest manubrio. Uniformitas intervalli cultris facile exacte regari potest.

3. Custos tutela et interclusio electrica operationem tutam garant.

4. Plata constringens machinae instructa est separato apparatu constringente hydraulico, et singulus apparatus constringens habet pedem plasticum ad extremum suum.

5. Systema CNC specialis, E20, adhibetur ad machinam secantem materialem stop posterioris. Numerus sectionum digitaliter ostendi potest.

6. Apparatus supportionis volventis non solum resistentiam frictionalem minuit, sed etiam garantis superficiem operis non laedi.

7. Structura tota ex componentibus alti fortitudinis, plene soldatis ex ferro constat; haec descriptio internas tensiones eliminat, quod ad altiorem vim et excellentem rigorem ducit.

8. Systema motus sursum transmissionis hydraulicae utitur, operationem lenem et fidam praebens.

Specifications

| Typus instrumenti machinalis | Maxima crassitudo laminaris (mm) | Maxima latitudo laminaris (mm) |

Angulus secandi | Numerus ictuum | Intervalum limitis posterioris (mm) | Potentia motoris principalis (YW) |

| QC12Y-4×2500 | 4 | 2500 | 1°30' | 18 | 20-600 | 4 |

| QC12Y-4×3200 | 4 | 3200 | 1°30' | 18 | 20-600 | 7.5 |

| QC12Y-4×4000 | 4 | 4000 | 1°30' | 12 | 20-600 | 7.5 |

| QC12Y-4×6000 | 4 | 6000 | 1°30' | 7 | 20-800 | 11 |

| QC12Y-6×2500 | 6 | 2500 | 1°30' | 18 | 20-600 | 7.5 |

| QC12Y-6×3200 | 6 | 3200 | 1°30' | 14 | 20-600 | 7.5 |

| QC12Y-6×4000 | 6 | 4000 | 1°30' | 12 | 20-600 | 7.5 |

| QC12Y-6×6000 | 6 | 6000 | 1°30' | 8 | 20-800 | 11 |

| QC12Y-8×2500 | 8 | 2500 | 1°30' | 14 | 20-600 | 11 |

| QC12Y-8×3200 | 8 | 3200 | 1°30' | 12 | 20-600 | 11 |

| QC12Y-8×4000 | 8 | 4000 | 1°30' | 10 | 20-600 | 11 |

| QC12Y-10×2500 | 10 | 2500 | 1°30' | 10 | 20-600 | 11 |

| QC12Y10×3200 | 10 | 3200 | 1°30' | 10 | 20-600 | 11 |

| QC12Y-10×4000 | 10 | 4000 | 1°30' | 8 | 20-600 | 11 |

| QC12Y-12×2500 | 12 | 2500 | 2° | 10 | 20-600 | 15 |

| QC12Y-12×3200 | 12 | 3200 | 2° | 9 | 20-600 | 15 |

| QC12Y-12×4000 | 12 | 4000 | 2° | 8 | 20-600 | 18.5 |

| QC12Y-16×2500 | 16 | 2500 | 2° | 8 | 20-800 | 18.5 |

| QC12Y-16×3200 | 16 | 3200 | 2° | 7 | 20-600 | 18.5 |

| QC12Y-16×4000 | 16 | 4000 | 2° | 6 | 20-600 | 18.5 |

| QC12Y-20×2500 | 20 | 2500 | 2°30' | 7 | 20-800 | 22 |

| QC12Y-20×3200 | 20 | 3200 | 2°30' | 6 | 20-800 | 22 |

| QC12Y-20×4000 | 20 | 4000 | 2°30' | 5 | 20-800 | 22 |

| QC12Y-25×2000 | 25 | 2000 | 3° | 8 | 20-800 | 37 |

| QC12Y-25×2500 | 25 | 2500 | 3° | 6 | 20-800 | 37 |

| QC12Y-25×3200 | 25 | 2500 | 3° | 6 | 20-800 | 37 |

| QC12Y-25×4000 | 25 | 4000 | 3° | 5 | 20-800 | 37 |

| QC12Y-32×2500 | 32 | 2500 | 3.5° | 5 | 20-1000 | 45 |

| QC12Y-32×3200 | 30 | 3200 | 3.5° | 5 | 20-1000 | 45 |

| QC12Y-40×2500 | 40 | 2500 | 4° | 4 | 20-1000 | 55 |

| QC12Y-40×3200 | 40 | 3200 | 4° | 4 | 20-1000 | 75 |

| QC12Y-50×2500 | 50 | 2500 | 4° | 3 | 20-1000 | 90 |

Nivelare Machina Soluta

Nivelare Machina Soluta Machina Forficis

Machina Forficis Facies Laser Incisoria

Facies Laser Incisoria Machina Frangendi Pressa

Machina Frangendi Pressa Rolling Machine

Rolling Machine Machina Pressoria Hydraulica

Machina Pressoria Hydraulica Ferrum Coniunctivum

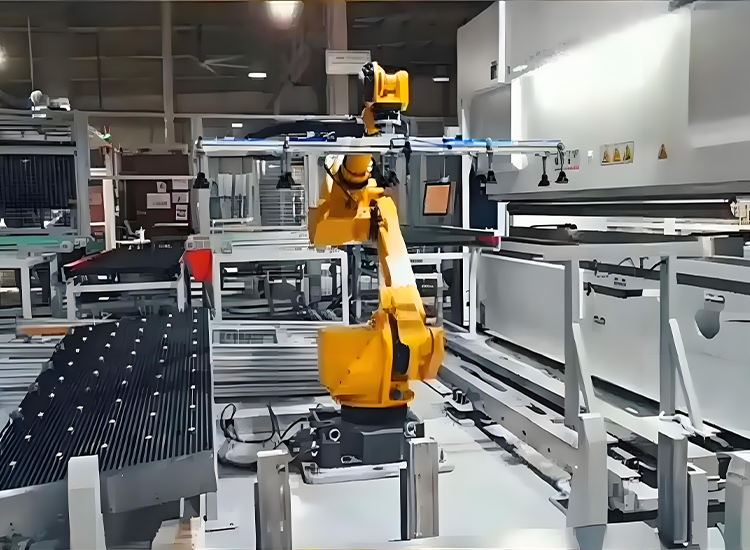

Ferrum Coniunctivum Robot Arm

Robot Arm