- Conspectus

- Producta Commendata

| Locus originis: | China |

| Nomen marcae: | WEILI |

| Numerus modeli: | CHK-6×2500, CHK-6×3200, etc. |

| Certificatio: | ISO9001 |

| Quantitas minima ordinis: | 1 |

| Pretium: | Dependente a numero moduli |

| Particularia impaquetandi: | Cista lignea, impermeabilis |

| Tempus solutionis: | 20 Diesibus |

| Conditiones solutionis: | praestatio 30%, solvere reliquum 70% ante distributionem |

| Vis Supplicandi: | Capacitates manufacturales adordines magnae magnitudinis |

● Machina hydraulica secans secundae generationis structuram totam ex ferro soldatam habet, cum tractatione thermica ad internas tensiones tollendas, quae rigidiorem et stabiliorem reddit.

● Structura tota ex laminis ferreis soldatis constat, cum tecto robusto et rigidiore optima atque validis facultatibus ad sorbendum ictus.

● Pretii alti pro pecunia, valida potentia technica, certitudo qualitatis et durabilitas.

Descriptio

Systema CNC speciale pro Falcis E22S

● Monitor LCD altius definitionis. Disponibilis tam Sinice quam Anglice, parametra programmationis in una pagina ostendens, ut programmare celerius et commodius possis.

● Intelligentis dispositio positionandi secundum axes X et Y, etiam manu regolabilis si opus sit, necesse non habens machinalium dispositivorum manubrialium ad positionem.

● Innata functio temporis tenendi et dilationis evadendi, operationem faciliorem efficiens. Nullum necessarium relais tempore, impensas minuens.

● Functio unico ictu parametrorum servandorum et recuperandorum, ut parametri quando opus restitui possint, maintenanceque impensas minuantur.

● Programmatio plurium graduum admittitur, ut partes complexas uno actu elaborare possis, efficacitatem productionis et praecisionem elaborandi meliorans.

● Omnes buttonae in tabula sunt micro-interruptores qui rigorisibus experimentis, ut EMC, altis et bassis temperaturebus, vibrationibusque, subiecti sunt, ut stabilitas et ducata producti certa sit.

● Certificatum CE adeptus est, necessitudines mercati transmarini adimplet.

Specifications

| Numerus Modeli | Spissitudo secantis laminæ | Latitudo secantis laminæ | Numerus totus cursuum | Cursus limitis posterioris | Cursus supportis anterioris | Angulus secandi | Pondus | Potentia motoris principalis | Magnitudo (L×L×A) |

| mm | mm | min¹ | mm | mm | ° | kG | kw | mm | |

| CHK-6×2500 | 6 | 2500 | 8-12 | 10-800 | 800 | 0.5-1.5 | 5500 | 7.5 | 3200×1800×2050 |

| CHK-6×3200 | 6 | 3200 | 8-12 | 10-800 | 800 | 1.5 | 6400 | 7.5 | 3800×1800×2050 |

| CHK-6×4000 | 6 | 4000 | 8-12 | 10-800 | 800 | 0.5-1.5 | 9000 | 7.5 | 4600×1970×2050 |

| CHK-6×5000 | 6 | 5000 | 8-10 | 10-800 | 1000 | 0.5-1.5 | 14000 | 7.5 | 5600×2400×2450 |

| CHK-6×6000 | 6 | 6000 | 8-10 | 10-800 | 1000 | 0.5-1.5 | 18000 | 7.5 | 6600×2400×2450 |

| CHK-8×2500 | 8 | 2500 | 8-12 | 10-800 | 800 | 0.5-1.5 | 7000 | 11 | 3200×2000×2100 |

| CHK-8×3200 | 8 | 3200 | 8-10 | 10-800 | 800 | 0.5-1.5 | 7800 | 11 | 3800×2000×2200 |

| CHK-8×4000 | 8 | 4000 | 8-12 | 10-800 | 800 | 0.5-1.75 | 9800 | 11 | 4600×1970×2050 |

| CHK-8×5000 | 8 | 5000 | 7-9 | 10-800 | 1000 | 0.5-1.5 | 18000 | 22 | 5600×2400×2450 |

| CHK-8×6000 | 8 | 6000 | 7-9 | 10-800 | 1000 | 0.5-2 | 22000 | 22 | 5700×2400×2550 |

| CHK-10×2500 | 10 | 2500 | 8-10 | 10-800 | 800 | 0.5-2 | 8500 | 18.5 | 3200×2000×2200 |

| CHK-10×3200 | 10 | 3200 | 8-10 | 10-800 | 800 | 0.5-2.5 | 9500 | 18.5 | 3800×2400×2600 |

| CHK-10×4000 | 10 | 4000 | 8-10 | 10-800 | 800 | 0.5-2.5 | 13000 | 18.5 | 4600×1970×2350 |

| CHK-12×2500 | 12 | 2500 | 9-12 | 10-800 | 1000 | 0.5-2.5 | 9000 | 18.5 | 3200×2200×2400 |

| CHK-12×3200 | 12 | 3200 | 8-12 | 10-800 | 800 | 0.5-2 | 10000 | 18.5 | 3800×2200×2450 |

| CHK-12×4000 | 12 | 4000 | 8-10 | 10-800 | 800 | 0.5-2 | 15000 | 18.5 | 4600×2300×2450 |

| CHK-12×5000 | 12 | 5000 | 6-8 | 10-900 | 800 | 0.5-2 | 24000 | 18.5 | 5600×2400×2550 |

| CHK-12×6000 | 12 | 6000 | 6-8 | 10-800 | 1000 | 0.5-2 | 28000 | 18.5 | 6800×2450×2550 |

| CHK-16×2500 | 16 | 2500 | 8-10 | 10-800 | 1000 | 0.5-2.5 | 11500 | 22 | 3200×2200×2400 |

| CHK-16×3200 | 16 | 3200 | 8-10 | 10-800 | 800 | 0.5-2.5 | 12800 | 22 | 3800×2200×2650 |

| CHK-16×4000 | 16 | 4000 | 6-9 | 10-900 | 800 | 0.5-1.5 | 17800 | 22 | 4600×2300×2650 |

| CHK-16×5000 | 16 | 5000 | 5-7 | 10-800 | 800 | 1.5-3 | 28000 | 22 | 5600×2400×2850 |

| CHK-20×2500 | 20 | 2500 | 6-9 | 10-800 | 800 | 0.5-2.5 | 14200 | 30 | 3200×2200×2400 |

| CHK-20×3200 | 20 | 3200 | 6-9 | 10-800 | 800 | 0.5-2.5 | 16000 | 30 | 3800×2200×2650 |

| CHK-20×4000 | 20 | 4000 | 6-9 | 10-800 | 1000 | 0.5-2.5 | 26000 | 30 | 4600×2300×2850 |

| CHK-20×5000 | 20 | 5000 | 4-6 | 10-800 | 1000 | 1.5-3.5 | 33000 | 30 | 5600×2400×2950 |

| CHK-20×6000 | 20 | 6000 | 4-6 | 10-800 | 1000 | 1.5-3.5 | 44000 | 30*2 | 6800×2450×3050 |

| CHK-25×2500 | 25 | 2500 | 6-9 | 10-800 | 800 | 0.5-2.5 | 20000 | 45 | 3300×2500×2900 |

| CHK-25×3200 | 25 | 3200 | 6-9 | 10-800 | 1000 | 0.5-2.5 | 22000 | 45 | 4200×2500×3200 |

| CHK-25×4000 | 25 | 4000 | 6-9 | 10-800 | 1000 | 0.5-2.5 | 37000 | 55 | 4980×2650×2700 |

Nivelare Machina Soluta

Nivelare Machina Soluta Machina Forficis

Machina Forficis Facies Laser Incisoria

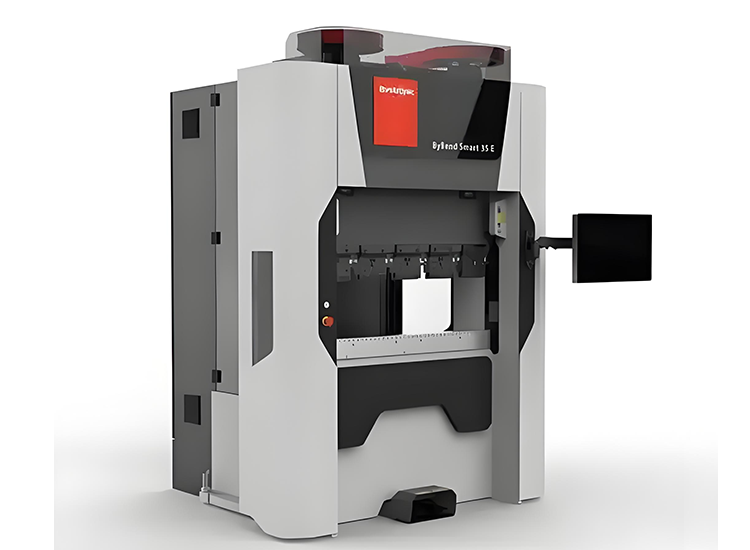

Facies Laser Incisoria Machina Frangendi Pressa

Machina Frangendi Pressa Rolling Machine

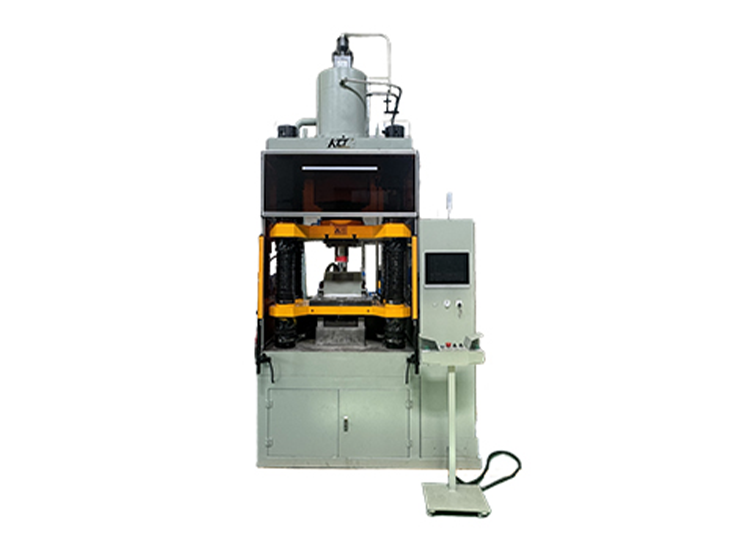

Rolling Machine Machina Pressoria Hydraulica

Machina Pressoria Hydraulica Ferrum Coniunctivum

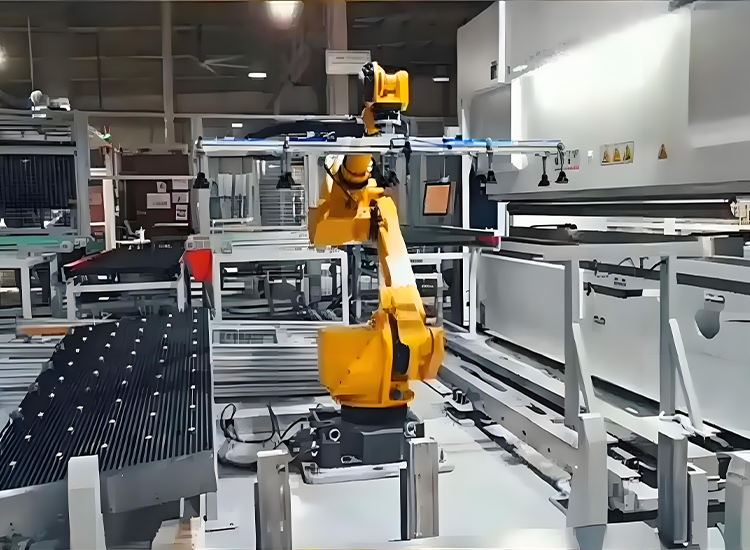

Ferrum Coniunctivum Robot Arm

Robot Arm